In the field of mechanical manufacturing and engineering, washers are indispensable connecting components, and the choice of their materials is crucial. Common metal washer materials such as carbon steel and stainless steel are widely used for their good mechanical properties and corrosion resistance. Common metal washers are made of carbon steel and stainless steel. In addition, what other metal washers are more common?

300 Stainless Steel Series

304 Stainless Steel

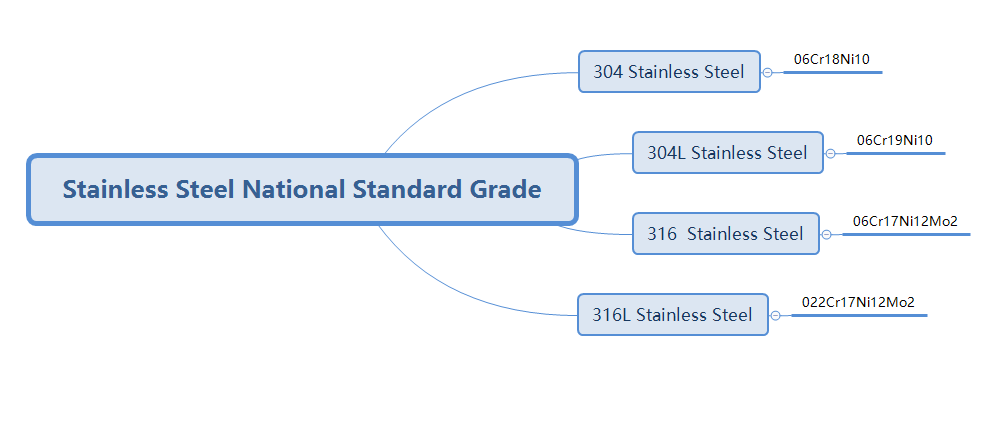

Let's talk about stainless steel washers first. The most representative ones are 304, 304L, 316, and 316L stainless steel, which have good anti-corrosion and anti-rust properties.304 stainless steel is 06Cr18Ni10 in the national standard, also called 18/8 stainless steel, which means that it contains 18%-20% chromium (Cr) and 8%-10% nickel (Ni), and it is -196℃ to 538 At temperatures of ℃, stress corrosion and intergranular corrosion are prone to occur. The suitable working temperature of 304 stainless steel gaskets cannot exceed 760°C.

304L Stainless Steel

304L stainless steel is marked as 06Cr19Ni10 in the national standard, where the L refers to the decarbonization process, and its carbon content does not exceed 0.03%, which can improve its resistance to intergranular corrosion. The suitable working temperature of 304L stainless steel gaskets cannot exceed 760°C.

316 Stainless Steel

316 stainless steel is marked as 06Cr17Ni12Mo2 in the national standard. It contains more molybdenum (Mo) alloy than 304 stainless steel, and the nickel (Ni) content is increased by 2%-3%. The stainless steel 18/12 that many people refer to is 316 stainless steel. Higher strength and corrosion resistance, and higher creep resistance as temperatures rise. The suitable working temperature of 316 stainless steel gaskets cannot exceed 760°C.

316L Stainless Steel

316L stainless steel is marked as 022Cr17Ni12Mo2 in the national standard. After decarbonization treatment, it has stronger stress resistance and improved intergranular corrosion resistance. The suitable working temperature of 316L stainless steel gasket should not exceed 815℃.

Carbon Steel

Carbon steel is also a very representative gasket material. Carbon steel has better plasticity, toughness and weldability. The higher the carbon content, the better its strength and hardness, but the plasticity, toughness and weldability will be reduced accordingly.

The suitable working temperature of carbon steel washers should not exceed 538°C, especially in oxidizing media, the temperature cannot be too high. When manufacturing equipment for inorganic acids, neutral or acidic salt solutions, if carbon steel gaskets are used, the equipment is prone to failure under hot water conditions; however, carbon steel gaskets can be used for manufacturing equipment for high-concentration acid and alkali solutions.

20 Alloy

20 alloy is a type of alloy steel with excellent resistance to sulfuric acid corrosion. Its elements are mainly iron and nickel. Its general composition is 45% iron (Fe), 24% nickel (Ni), 20% chromium (Cr) and a small amount. Molybdenum (Mo) and copper (Cu). The suitable working temperature of 20 alloy gaskets should not exceed 815°C.

Aluminum

Aluminum (Al) has good corrosion resistance and processability. The aluminum content in aluminum gaskets should not be less than 99%, and its suitable working temperature should not exceed 426°C, such as double-clamp gaskets.

Brass

Brass refers to an alloy material with a copper (Cu) content of 66% and a zinc (Zn) content of 34%. Under most working conditions, its corrosion resistance is good, but it is not suitable for acetic acid, ammonia, salt and acetylene. The suitable working temperature of brass washers cannot exceed 260°C.

Copper

The composition of red copper is close to pure copper (Cu), and it contains trace amounts of silver (Ag) to increase its continuous working temperature. The maximum continuous operating temperature of the copper gasket should not exceed 260°C.

Hastelloy

Hastelloy is a nickel-based corrosion-resistant alloy. Its main components are nickel-chromium alloy and nickel-chromium-molybdenum alloy. It has good corrosion resistance and thermal stability. Hastelloy alloys commonly used in the production of gaskets include Hastelloy B-2 (00Ni70Mo28) and Hastelloy C-276 (00Cr16Mo16W4). The suitable working temperature of these two types of gaskets cannot exceed 1093°C.

Titanium

Titanium (Ti) still has excellent corrosion resistance under high temperature conditions. It can resist corrosion by nitric acid, chloride ions, etc. within a wide temperature and concentration range. The suitable working temperature of titanium gaskets is not higher than 1093°C.

Other Nickel-based Alloys

Inconel600 nickel-based high-temperature alloy is a nickel-cobalt-aluminum series metal with high temperature resistance, corrosion resistance and high strength. Its composition is 77% nickel (Ni), 15% chromium (Ni), and 7% iron (Fe). Under high temperature conditions, its strength is still very high, and it is mostly used in equipment to solve stress corrosion problems. Under low temperature conditions, it still has excellent processing performance. The suitable working temperature of Inconel600 alloy gaskets cannot exceed 1093°C.Monel 400 alloy is a nickel-based alloy with good corrosion resistance in various media such as seawater, chemical solvents, ammonia, sulfur, chlorine, hydrogen chloride, sulfate, hydrochloric acid, phosphoric acid and other acidic media, alkaline media, salts and molten salts. Alloy materials. The maximum continuous operating temperature of Monel 400 alloy gaskets should not exceed 815°C.

That's all for the various metal materials used to produce washers. Find more washer products? Contact us now!