In the industrial industry, linear transmission mechanisms are divided into many types. What types are there? What are the differences between these types? What are the advantages and disadvantages of each?

The types of linear transmission mechanisms can be divided into the following 10 types. When purchasing products, you can reduce a lot of wasted effort by choosing according to the required movement.

Trapezoidal Screw

The trapezoidal screw is named after its tooth cross section is trapezoidal.

Transmission efficiency: The transmission efficiency of the trapezoidal screw is about 26~46%.

Transmission speed: The trapezoidal screw has sliding friction and the temperature rises greatly during operation, so it cannot be used for high-speed transmission.

Service life: The sliding friction surface is severely damaged, so the service life is low. Pay attention to cleaning and lubrication during normal use.

Self-locking: Self-locking is generally inversely proportional to transmission efficiency. Therefore, the trapezoidal screw has a certain degree of self-locking.

Economical: The one-time completion process is very efficient, so the cost is low. However, due to the development of ball screws and the upgrading and transformation of process supporting equipment, there may be an increase in the number in the future.

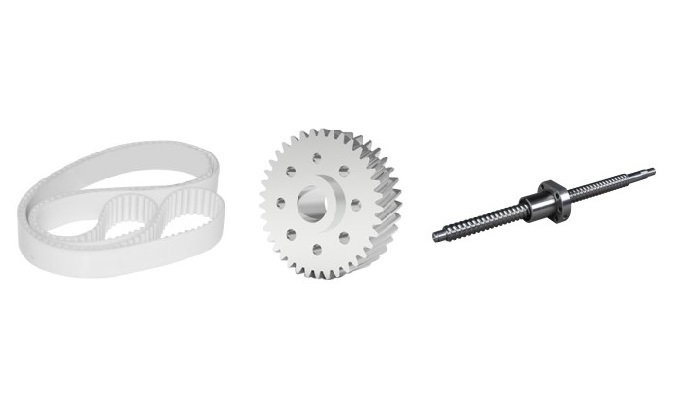

Ball Screw

The ball screw is composed of screw, nut, steel ball, preloading piece, reverser and dust protector.

Features: Small friction loss and high transmission efficiency. Since there are many balls performing rolling motion between the screw shaft and the screw nut of the ball screw pair, a higher motion efficiency can be obtained, generally up to 90~96%.

High precision: Ball screw production equipment is expensive and high-precision equipment. The batch production process minimizes the interference of human factors on the accuracy of production.

High-speed feed and micro-feed possible: Because the ball screw pair uses ball motion, the static friction is small, so the starting torque is extremely small, there will be no crawling phenomenon, and accurate micro-feed can be ensured.It cannot be self-locking and has the reversibility of transmission.

Timing Belt

The timing belt uses steel wire or glass fiber as the strong layer and is covered with polyurethane or rubber. The inner circumference of the belt is made into a tooth shape so that it meshes with the toothed pulley.

The timing belt has compact structure, oil resistance, good wear resistance and good anti-aging performance. The general operating temperature is minus 20℃-80℃, vThe transmission is accurate, there is no slippage during operation, and it has a constant transmission ratio.

The transmission is smooth, has buffering and vibration reduction capabilities, and has low noise. The transmission efficiency is high, up to 0.98, and the energy saving effect is obvious, maintenance is convenient, no lubrication is required, and maintenance costs are low. It can be used for long-distance transmission, and the center distance can reach more than 10 m.

Electric Push Rod

Also called push rod motor, linear drive. Its characteristics include small size, large thrust, good self-locking performance, direct motor drive, and no need for air or oil pipelines, but it cannot withstand radial loads. It is mostly used in civilian fields such as ventilating windows and stages.

Electric Cylinder

The electric cylinder is also called an electric actuator, the electric cylinder is a modular product that integrates a servo motor and a screw. It adopts closed-loop servo control with a control accuracy of 0.01mm; with the addition of a pressure sensor, the thrust control accuracy can reach 1%. Noise Low, high rigidity, impact resistance, simple operation and maintenance. There are many applications in industrial fields.

Linear Motor

It does not require any intermediate conversion mechanism transmission device. It can be seen as a rotating motor cut into radial sections and flattened.

Simple structure: The linear motor directly generates linear motion without going through an intermediate conversion mechanism, which greatly simplifies the structure and reduces the motion inertia, thus achieving higher acceleration, dynamic response and positioning accuracy. Because of the circular transformation, ordinary materials can also reach higher speeds. There is a gap between the stator and the mover, and there is no mechanical contact during movement, so there is no friction and noise, and it has a high life.

Gear Rack

Features: Large bearing capacity; simple structure, reliable operation; unlimited length of docking and continuation, transmission speed can be very high, >2m/s.

Disadvantages: Poor accuracy, loud transmission noise, and large wear, lubricating oil needs to be added, which easily pollutes the on-site environment and is not conducive to use in a dust-free environment.

Typical uses: construction elevators can reach 30 stories high.

Cam Mechanism

Features: The structure is simple, compact and convenient in design. As long as the appropriate cam profile is made, the driven rod can obtain any predetermined movement pattern.

Disadvantages: The cam has high contact (point or line) pressure, and point and line contact are easy to wear, the cam profile is difficult to process and the cost is high, the stroke is not large.

Cylinder Mechanism

Features: Simple to use, easy to install and maintain; highly adaptable. The cylinder can work normally in high and low temperature environments and is dustproof and waterproof, and can adapt to various harsh environments.

Shortcoming: The control accuracy is low, usually two-point control, which requires an air compressor, and there is a risk of air leakage when starting the transmission. Various pneumatic lines need to be installed and maintained. A continuous supply of pressure is required. The response speed is slow and it is not suitable for complex circuits with too many component levels.

Hydraulic Cylinder

It has the characteristics of low speed and heavy load, and the maximum thrust can reach hundreds of thousands of tons, it is usually used in heavy industry, such as forging, etc.