In non-standard design, aluminum profiles are frequently used for their aesthetically pleasing appearance post-oxidation, along with the convenience of assembly using specialized accessories—eliminating the need for welding and promoting environmental friendliness. The diverse array of aluminum profile connection methods is a testament to the versatility of these materials. Our mechanical enthusiast editor, though diligent, can't cover every method exhaustively. Here, we briefly introduce 20 aluminum profile connection methods with visual demonstrations through animated graphics for easy comprehension and reference:

1. Built-in Connectors

Used for a 90° connection between two profiles with a hidden and high-strength connection.

Intermediate connection method:

2. Angle Brackets (90°, 45°, 135°)

Employed for externally connecting profiles at fixed angles (90°, 45°, 135°) and securing cover panels.

Die-cast aluminum right-angle connection:

Extruded aluminum right-angle connection:

45°, 135° connections:

3. Screw Connections

Suitable for a 90° internal connection of two profiles, offering easy installation and disassembly, commonly used for simple profile enclosures.

Different styles of screw connections:

4. L-shaped Groove Connectors (90°)

Designed for a straightforward 90° connection of two profiles, with simple installation and no additional machining required.

5. High-Strength Groove Connectors (45°)

Intended for internally connecting two profiles at a 45° angle, providing high strength, often used for securing door frame profiles.

6. End Face Connectors

Used for a right-angle connection between two or three profiles, ensuring robustness and aesthetic appeal.

7. Three-Dimensional Connectors (Right Angle)

Applied for a right-angle connection between three profiles, offering convenient and quick connections.

8. Three-Dimensional Connectors (R Angle)

Used for a right-angle connection between three curved profiles, providing easy and quick connections.

9. Elastic Fasteners

Employed for a 90° internal connection of two profiles, ensuring convenient installation and disassembly.

10. End Connectors

Designed for a 90° internal connection between two profiles, featuring a concealed connection and high strength.

11. Cross Connectors

Used for a high-strength diagonal connection of two profiles.

12. Anchor Connectors

Suitable for connecting two profiles at various angles, featuring a concealed connection for easy profile installation.

13. Articulated Hinges

Applied for connecting two profiles with an adjustable range from 30° to 150°.

14. Turning Connection Plates

Used for various profile connections, allowing multi-angle rotation.

15. Connection Plates

Designed for connecting multiple profiles, providing high connection strength without the need for machining, ensuring easy installation.

16. Turning Angle Brackets for Arbitrary Profile Connections

Enables the connection of profiles at any angle.

17. Bolt Head Components

Incorporates elastic nuts into one profile and cylindrical columns into another, secured using bolts.

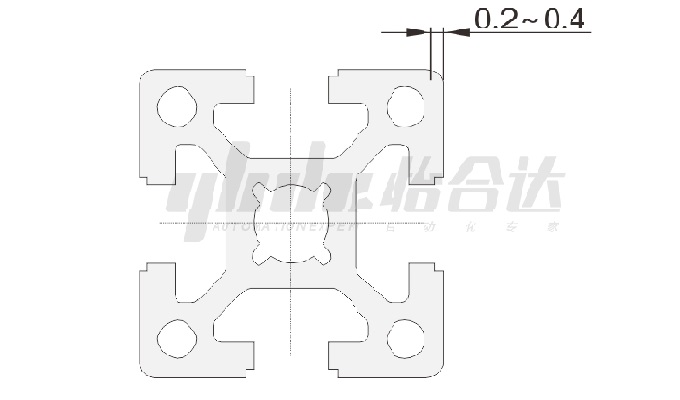

18. Cross-shaped Exterior Connection Plates

Used for high-strength connections in a "plus" shaped configuration of a single groove profile.

19. L-shaped, T-shaped Exterior Connection Plates

Designed for high-strength connections in "L" or "T" shaped configurations of a single groove profile.

20. Y-shaped Exterior Connection Plates

Applied for high-strength connections in a "-" shaped configuration of a single groove profile.