In this comprehensive guide, we will delve into the world of shaft supports and provide invaluable insights to help you navigate this crucial machinery component. Whether you're a seasoned professional or a curious enthusiast, this guide will equip you with the knowledge and understanding to make informed decisions regarding shaft supports. So, let's embark on this enlightening journey together and unlock the secrets of optimal shaft support systems.

What is the shaft support?

It supports and fixes the guide shaft and, simultaneously, can bear a certain load of the parts. The guide shaft, linear bearings, and oil-free bushings are used together to form a linear guide mechanism.

Structural characteristics of the guide shaft bearing

(1) Flange-type guide shaft bearing suits the scene where the guide shaft is perpendicular to the installation surface.

(2) Square-type guide shaft bearing applies to the scenario where the mounting surface is parallel to the guide shaft.

(3) The stop screw type guide shaft holder is easy to install and cost-effective.

(4)) Support part thickening type guide shaft bearing makes the support more stable.

(5) The open-type guide shaft support will not damage the guide shaft, and the guide shaft axis is easy to disassemble and install.

(6) Compact-type guide shaft support is more suitable for small spaces.

(7) The guide shaft installation with a large axial load uses the end-fixed type guide shaft support.

(8) Separate type guide shaft support is especially suitable for the case where the guide shaft needs to be disassembled and installed several times.

(9) Guided shaft support suits the scenario where accurate positioning is required.

(10) The cast-type guide shaft bearing is less expensive and has many applications.

Main types of shaft support

1. Flange type

2. T/L type guide shaft bearing

3. Compact type guide shaft bearing

4. Base mount type, side mount type

Flange-type guide shaft bearing is further divided into.

1. Round flange type

2. Flange type

3. Flange type with opposite sides

Flange type guide shaft bearing main material: S45c, suS304

Flange-type guide shaft bearing surface treatment: blackened, electroless nickel plating, natural color anodizing, black anodizing, etc.

T/L type guide shaft bearing

Main material: S45c, SUS304, A6063

Surface treatment: blackening, electroless nickel plating, natural anodizing, black anodizing

Compact guide shaft support

Main material: S45c, sUS304.

Surface treatment: blackened, electroless nickel plating

Base mount type, side mount type

Main material: S45c, sUS304, A6063.

Surface treatment: blackened, electroless nickel plating, natural color anodized, black anodized.

Guide shaft support material introduction

1.S45C.

45 steel is a medium carbon quality steel with good overall mechanical properties and lower cost.

2.SUS304

SUS304 is commonly known as 304 stainless steel, with high corrosion resistance; in low temperature, room temperature, and high temperature, have high plasticity and toughness, unsuitable for heat treatment.

3.Aluminum alloy

A6063 aluminum alloy has low density but relatively high strength, is close to or more than high-quality steel, and is widely used.

How to choose the right guide shaft support

(1) According to the use of the scene selection

Guide the shaft and the installation surface perpendicular to the scene. Choose flange type. Guide shaft and the installation surface parallel to the case of the choice of square type.

(2) According to the guide shaft force selection

The thickened type should be used when the guide shaft needs to bear a large radial load. The end mounting type should be used when the guide shaft needs to bear a large axial load.

(3) According to the disassembly and installation requirements of the guide shaft

If the guide shaft is fixed, the stop screw type can be used, which is easy to install and cost-effective.

The guide shaft to be disassembled should be selected for open-type support, will not damage the shaft, and is easy to disassemble. Choose the separation type if the guide shaft needs to be disassembled frequently. Easy to use.

(4) According to the use of environmental selection

The general-use environment can choose carbon steel-blackened products, cost-effective. Nickel-plated products have high strength and good rust resistance.

Higher strength requirements and rust prevention requirements can choose stainless steel products. Aluminum alloy surface oxidation products have high rust resistance and are light to use. (5) According to the guiding shaft positioning requirements

Radial positioning requirements of the choice of guide shaft support or flange with positioning hole type. For axial positioning requirements, use the square type with positioning holes.

(6) Special application scenarios

The compact type can be used for small spaces. For the bottom locking screw, please choose the bottom mounting type. The side mounting type can be used for side fixing. You can use the handle type support if you need to lock quickly.

Selection in the process of use.

1. Flange-type guide shaft support is mostly used for vertical direction guide shaft fixing.

2. L/T type guide shaft support is mostly used for guide shaft horizontal direction moving fixed.

How to install and remove the guide shaft bearing

(1) Blackening products should be avoided in a humid environment; installation should avoid sweaty and wet hands directly touching the product. After installation and use, anti-rust oil should be regularly sprayed to prevent rust treatment.

(2) Aluminum alloy products are light to use and have good rustproof performance, and should avoid high-intensity use when using.

(3) guide shaft support shaft mounting hole tolerance H7, generally with the use of the g6 axis, shaft processing should be matched with the corresponding tolerance to avoid the occurrence of the clamp does not tighten the situation.

Maintenance of the guide shaft support

(1) bore for the main tolerance with precision, should avoid bumping, cutting, etc., caused by bore burrs.

(2) Blackened products should be regularly anti-rust maintained to avoid rusting.

(3) Preservation and transportation should avoid dropping, smashing, bumping, and other damage that may cause the appearance of the product, surface treatment, etc.

(4) Other daily details of attention can be carefully noted.

The advantages and disadvantages of the guide shaft bearing

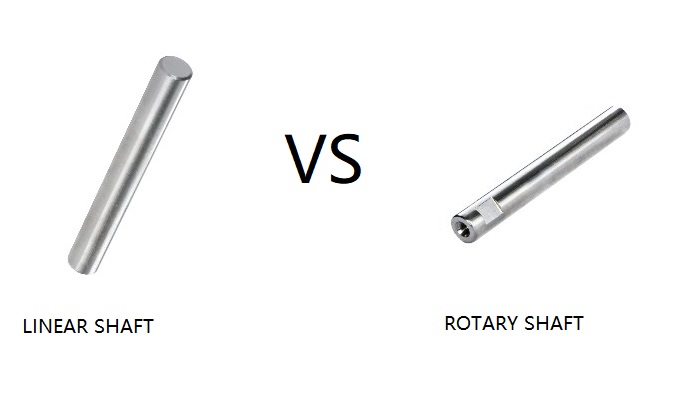

Guide shaft bearings are crucial in various machines and equipment that guide linear and rotational movements. While they offer many advantages, they also have some disadvantages that should be considered.

Advantages:

High precision: Guide shaft bearings offer high-precision guidance for linear and rotational movements, ensuring smooth and accurate operation.

Low friction: They provide low friction, which reduces wear and tear on the bearing and increases its lifespan.

High load capacity: Guide shaft bearings can withstand high loads, making them suitable for heavy-duty applications.

Low noise and vibration: These bearings operate with low noise and vibration, making them ideal for sensitive applications.

Low maintenance: Guide shaft bearings are relatively low, requiring only periodic lubrication to ensure proper operation.

Disadvantages:

Limited range of motion: Guide shaft bearings have a limited range of motion and are best suited for linear and rotational movements.

High cost: Some guide shaft bearings, particularly those with specialized designs and materials, can be expensive.

Prone to contamination: Guide shaft bearings are susceptible to contamination from dirt, dust, and other particles, which can damage the bearing and reduce its lifespan.

Installation complexity: Guide shaft bearings can be complex and require specialized tools and expertise.

In summary, guide shaft bearings offer high precision, low friction, high load capacity, and low noise and vibration. However, they have a limited range of motion, can be expensive, are prone to contamination, and may require specialized tools and expertise for installation.

Product surface treatment methods

1. Blackening: Blackening is low cost, simple equipment, easy to operate compared to galvanized chrome plating, low cost, has a good effect, and has lower corrosion resistance than other chemical films.

2. Electroless nickel plating: uniform thickness and uniform plating ability, corrosion resistance, high-temperature oxidation resistance, especially suitable for complex shapes, surface requirements of wear, and corrosion-resistant parts.

3. Natural anodizing: after anodizing aluminum or its alloys, the hardness and wear resistance of the film generated by anodizing is improved by a few microns to tens of microns, and hard and wear-resistant, good heat resistance, and enhanced corrosion resistance.

4. Black anodizing: the same as the original color anodizing, but the exterior color is different.

Example Case

As we conclude this guide, we hope it has shed light on the intricate world of shaft supports and provided you with the necessary guidance to make informed choices. Remember, selecting the right shaft support system is crucial for your machinery's smooth operation and longevity. By considering factors such as load capacity, misalignment tolerance, and installation requirements, you can ensure optimal performance and minimize the risk of premature failures.