I. What Are Mounted Bearings?

Mounted bearings are a kind of bearing unit that combines rolling bearings with bearing housings. Rolling bearings are installed together with machined bearing housings to form bearing units with diverse structural forms and good universality and interchangeability.

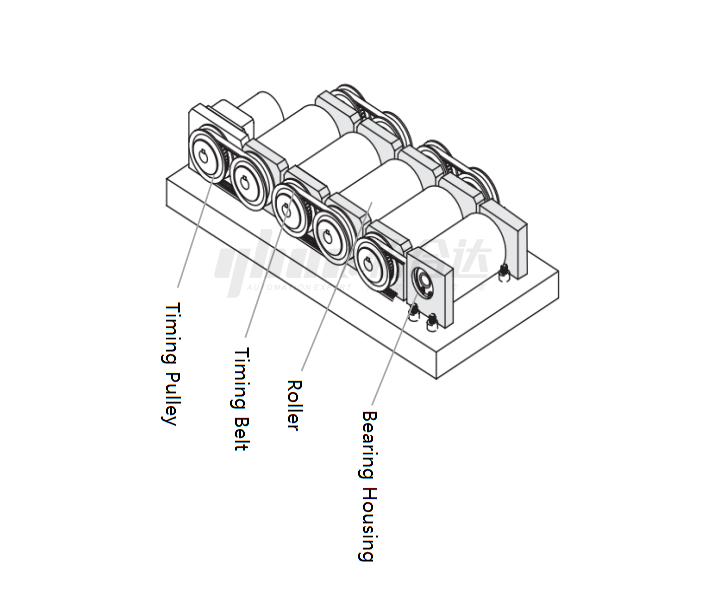

II. Product Composition

Mounted bearings consist of two parts: deep groove ball bearings or angular contact bearings or thrust ball bearings and a bearing housing.

The deep groove ball bearing is the most common type of rolling bearing. It has the advantages of simple structure, easy use, and low friction coefficient. In mounted bearings, deep groove ball bearings can bear relatively large radial loads and can also bear certain axial loads at the same time.

The angular contact bearing is suitable for occasions where relatively large axial and radial loads need to be borne. Its contact angle can be adjusted according to actual needs to meet different load requirements.

The thrust ball bearing is mainly used to bear axial loads and is usually used in combination with other types of bearings in mounted bearings to meet complex load conditions.

The bearing housing, as an important part of the mounted bearing, is usually made of materials such as cast iron, cast steel or aluminum alloy. Its shape and size are designed according to different bearing types and installation requirements to ensure that the bearing can be firmly installed in it.

III. Application Occasions

The main use is to support the rotating bodies of mechanical structures. It is often used for fixing rotating shafts and ensuring their rotation. It is applicable to heavy and light industries and is commonly seen in transmission equipment, conveying equipment, reduction gears, cages, etc.

In heavy industries, such as mining machinery, metallurgical equipment, and large cranes, mounted bearings can bear huge loads and impacts and ensure the stable operation of the equipment. In light industries, such as textile machinery, food processing machinery, and packaging machinery, mounted bearings meet the strict requirements in the production process with their characteristics of high precision and low noise.

Mounted bearings are often used for fixing rotating shafts and ensuring their rotation. In various transmission equipment, such as gearboxes, reducers, motors, etc., mounted bearings can ensure the precise rotation of rotating shafts and transmit power and torque. In conveying equipment, such as belt conveyors, screw conveyors, bucket elevators, etc., mounted bearings support the conveying rollers or chains to ensure the smooth conveyance of materials. In reduction gears, mounted bearings can bear the high loads during the deceleration process, reduce the rotational speed, and increase the torque. In components such as cages, mounted bearings also play a key supporting role.

IV. Mounted Bearing Features

- Effectively reduce the friction coefficient of mechanical loads in the transmission process of mechanical equipment

Mounted bearings adopt advanced lubrication technologies and materials and can form a uniform lubricating film inside the bearings, reducing direct contact between metals and thus reducing the friction coefficient. This not only improves the transmission efficiency, reduces energy loss, but also extends the service life of the bearings.

For example, in some high-speed operating mechanical equipment, the reduction of the friction coefficient can significantly reduce heat generation and wear, improving the reliability and stability of the equipment. Meanwhile, a low friction coefficient can also reduce the operating noise of the equipment and improve the working environment.

- Strong universality, stable installation, and convenient loading and unloading

The design of mounted bearings has a high degree of universality and can adapt to different types of mechanical equipment and installation requirements. Its standardized size and interface design make it very convenient to replace and install among different equipment.

Stable installation is another important feature of mounted bearings. The structural design of the bearing housing is reasonable and can be closely combined with the installation foundation to ensure that the bearings will not become loose or displaced during operation. Meanwhile, mounted bearings are usually equipped with various installation accessories, such as bolts, nuts, washers, etc., facilitating users' installation and fixation.

Convenient loading and unloading is also a major advantage of mounted bearings. When maintaining equipment and replacing bearings, users can easily remove the mounted bearings from the equipment for inspection or replacement. This convenient loading and unloading method greatly improves the maintenance efficiency of the equipment and reduces the maintenance cost.

- High load capacity and low working noise

Mounted bearings have a relatively large load capacity and can bear various types of loads, including radial loads, axial loads, and combined loads. This benefits from its high-quality materials and advanced manufacturing processes, enabling the bearings to maintain good performance under high load conditions.

During the working process, the noise generated by mounted bearings is very small. This is because the contact between the rolling elements and raceways inside the bearings is very smooth, and the friction coefficient is low, thus reducing the generation of vibration and noise. In addition, the design of the bearing housing also plays a certain role in noise reduction and can effectively absorb and isolate the noise generated by the bearings.

- Long service life

The long service life of mounted bearings mainly benefits from its high-quality materials, advanced manufacturing processes, and good lubrication conditions.

In terms of materials, mounted bearings are usually made of high-strength alloy steel, stainless steel or ceramic materials, etc., with good wear resistance, corrosion resistance and fatigue resistance. In terms of manufacturing processes, precision machining technologies are adopted to ensure the dimensional accuracy and surface quality of the bearings, improving the bearing capacity and service life of the bearings.

Good lubrication conditions are also one of the key factors in extending the service life of mounted bearings. By reasonably selecting lubrication methods and lubricants, a stable lubricating film can be formed inside the bearings to reduce friction and wear and extend the service life of the bearings.

- Good sealing performance

Mounted bearings have good sealing performance and can effectively prevent external substances such as dust, moisture, and impurities from entering the inside of the bearings to protect the normal operation of the bearings.

The sealing structure usually adopts forms such as rubber sealing rings and metal dust covers, which can be selected according to different working environments and requirements. For example, in harsh working environments, contact-type rubber sealing rings with better sealing performance can be selected; in high-speed operation occasions, non-contact rubber sealing rings or metal dust covers with small friction can be selected.

V. Mounted Bearing Selection Principles

Key Points for Selecting Mounted Outer Spherical Bearings

The correct selection of mounted outer spherical bearings is an important link in giving play to the performance of the bearings and ensuring the normal operation of the main machine. When selecting suitable mounted outer spherical bearing models that meet the requirements of the main machine from various bearings and bearing housings, the following factors need to be considered:

(1) The requirements of the machine's own structure for the supports;(2) The requirements of the space at the installation site for the size of the bearing housing;

(3) The magnitude, direction, and nature of the load borne by the bearing housing;

(4) The requirements for the service life and reliability of the bearing housing;

(5) The requirements for the working speed of the bearings in the bearing housing;

(6) The positioning requirements of the bearing housing;

(7) The dust-proof requirements of the bearings in the bearing housing;

(8) The requirements for the temperature of the environment in which the bearing housing is used (high temperature resistance, low temperature resistance);

(9) The requirements for the surrounding media, dust prevention, moisture prevention, water prevention, etc. of the bearing housing;

(10) The strength requirements of the bearing housing;

(11) The economic requirements of the bearing housing.

VI. Installation Precautions

(1) For the installation of mounted bearings with machined parts, they should be fixed to the installation plate first and then the shaft should be installed. In principle, mounted bearings can be installed anywhere, but to ensure the service life of the bearings, the installation surface must be flat and firm.

(2) For mounted bearings with a blackening treatment on the surface, they should be avoided from being used in humid environments as much as possible. During installation, sweaty or wet hands should be avoided from directly contacting the product. After installation and during use, anti-rust oil should be sprayed regularly for anti-rust treatment.

(3) For back-to-back combined type mounted bearings, pay attention to the use of shaft collars.

(4) When using mounted bearings in pairs, pay attention to the concentricity of the installation.

VII. Maintenance and Care

- In principle, the bearing cover plate of deep groove ball mounted bearings is sealed with grease, and generally no additional lubrication is required.

The bearing cover plate of deep groove ball mounted bearings is usually sealed with an appropriate amount of grease, which can meet the lubrication needs of the bearings within a certain period of time. Under normal use conditions, generally no additional lubrication is required. However, in cases such as harsh use environments, high working temperatures, or large loads, it may be necessary to regularly check the state of the grease and supplement or replace it as needed.

- For needle thrust ball mounted bearings and back-to-back combined type mounted bearings, the grease is not sealed, and lubrication maintenance should be carried out regularly during the use process to ensure the performance and life of the bearings.

The grease of needle thrust ball mounted bearings and back-to-back combined type mounted bearings is usually not sealed, so lubrication maintenance needs to be carried out regularly during the use process. The frequency and method of lubrication can be determined according to the use conditions and working environment of the bearings. Generally speaking, tools such as grease guns or oil cups can be used for lubrication to inject an appropriate amount of grease into the inside of the bearings.

When carrying out lubrication maintenance, pay attention to selecting the appropriate grease. Different types of bearings and working environments require the use of greases with different properties, such as high-temperature grease, high-speed grease, waterproof grease, etc. Meanwhile, pay attention to the amount of grease injected to avoid adverse effects on the bearings caused by too much or too little grease.

VIII. Common Problems and Analyses

(1) If the installation surface is not flat, there will be differences in the center height of the mounted bearings used in pairs, which will cause seizure, increased friction, increased heat generation, and reduced life.

(2) Mounted bearings with deep groove ball bearings can bear relatively large radial forces, but their ability to bear axial forces is limited. Try to avoid bearing axial forces. To bear axial and radial forces, back-to-back combined type or needle thrust ball type mounted bearings can be purchased.

(3) Bearings are precision mechanical parts. Try to avoid impacts during use to avoid damage to the raceway surfaces or balls, which will cause increased friction of the supports, increased heat generation, and reduced life.

(4) Mounted bearings have different types of dust covers, and they should be correctly selected according to needs during use:

① ZZ is a metal dust cover with small friction, good high-speed performance, good sealing and dust-proof performance, but poor water-proof performance.

② VV is a non-contact rubber sealing ring with small friction, good high-speed performance, better sealing and dust-proof performance than metal dust covers, but poor water-proof performance.

③ DD is a contact rubber sealing ring with relatively large friction, poor high-speed performance, the best sealing and dust-proof performance, and good water-proof performance. It can be used in splash environments.

IX. Application Cases

(1) Conveying Mechanisms

(2) Transmission Mechanisms