Ball screw is the most common transmission method in linear transmission in non-standard fields. Today we will introduce the ball screw.

Introduction to Ball Screw

Ball screws are ideal products for converting rotary motion into linear motion or converting linear motion into rotary motion.

The ball screw is the most commonly used transmission element in tool machinery and precision machinery. Its main function is to convert rotational motion into linear or torque into axial repeated force. It also has high precision, reversibility, and high-efficiency characteristics. Due to its small frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

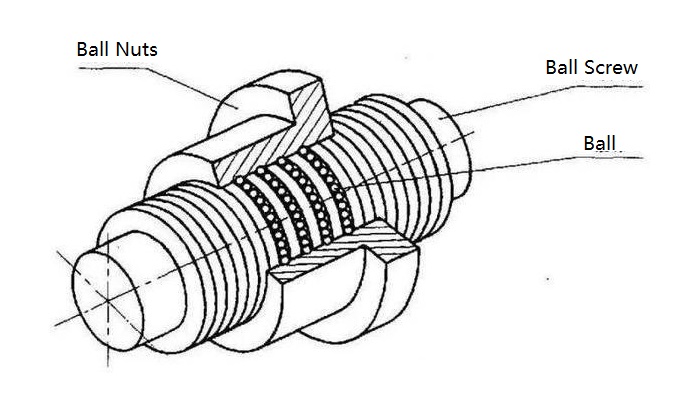

The ball screw comprises a screw, nut, steel ball, preloading piece, reverser, and dust protector. Its function is to convert rotational motion into linear motion, which is a further extension and development of the Acme screw. The important significance of this development is to change the bearing from sliding action to rolling action.

In short, the ball screw converts rotary motion into linear motion and linear motion into rotary motion.

The Composition and Classification of Ball Screws

The ball screw is composed of a screw shaft and a nut, and the nut is composed of steel balls, pre-pressed pieces, reversers, dust guards, etc. See below:

Types of Ball Screws

Precision Ball Screw

• Features: High precision and efficiency, suitable for applications requiring very accurate linear motion.

• Advantages: Provides excellent positioning accuracy, low friction and high efficiency, suitable for high-demand CNC machine tools and other precision equipment.

• Application: CNC machine tools, semiconductor manufacturing equipment, precision measurement equipment, etc.

High Load Ball Screw

• Features: Able to withstand greater axial loads, suitable for applications requiring handling of heavy workloads.

• Advantages: It has high load capacity and good rigidity, and can cope with the needs of large mechanical systems.

• Application: Metal cutting machine tools, injection molding machines, heavy machinery equipment, etc.

Rolled Ball Screw

• Features: Relatively simple manufacturing and low price.

• Advantages: Suitable for general applications requiring lower accuracy and more economical cost.

• Application: General automation equipment, industrial machinery, household machinery, etc.

Rolling Ball Screw

Ground Ball Screw

• Features: Manufactured by grinding, with higher precision and better surface quality.

• Advantages: Provides excellent positioning accuracy, suitable for applications requiring extremely high accuracy.

• Application: Precision instruments, optical equipment, medical equipment, etc.

Support Unit Ball Screw

• Features: Includes support units for applications requiring greater support and rigidity.

• Advantages: Provides stable support when bearing large loads, suitable for some heavy machine tools and systems with high rigidity requirements.

• Application: Spindle and feed system of machine tools, large mechanical devices, etc.

Support Unit Ball Screw

Miniature Ball Screw

• Features: Suitable for small size and light load applications.

• Advantages: Small size and lightweight design, suitable for applications with limited space.

• Application: Medical equipment, small robots, precision instruments, etc.

Double Nut Ball Screw

• Features: Two ball groups are installed on one nut to improve load-bearing capacity and rigidity.

• Advantages: Better resistance to vibration and increased system rigidity.

• Applications: Applications requiring higher rigidity and load capacity, such as high-speed machine tools.

According to the accuracy level, it is divided into rolling and grinding grade screws. The rolling screw has a relatively low accuracy and is suitable for situations where the accuracy requirements are not very high. The grinding grade screw has a relatively high accuracy and is ideal for applications with high accuracy requirements.

According to the ball circulation method, the nut can be divided into external circulation, inner circulation, and end cover type. Let's talk about the end cap type first. This is a relatively early structure, but its shortcomings are apparent. Now, it has been eliminated and is rarely used.

Let's focus on the inner and outer circulation:

The balls that sometimes break out of contact with the screw during the circulation process are called outer circulation; those that always remain in touch with the screw are called inner circulation. Each closed circuit of the ball is called a row, and the number of leads contained in each closed course of the ball is called the number of turns. Each nut of the internal circulation ball screw pair has 2 rows, 3 rows, 4 rows, 5 rows, etc., and each row has only one turn; each row of the outer circulation ball screw has 1.5 turns, 2.5 turns, and 3.5 turns.

1) External circulation:

External circulation is when the balls return to the space between the screw nut through the spiral groove or intubation on the outer surface of the nut and re-enter the circulation after the circulation process. As shown in Figure 2-3, the return methods of the external circulation ball screw nut pair during ball circulation mainly include end cap type, cannula type, and spiral groove type. Commonly used external circulation methods are end cap, intubation type, spiral groove type. End cover type, a longitudinal hole is machined on the nut as a return channel for the balls. The cover plates at both ends of the nut are provided with return ports for the balls, through which the balls enter the return pipe to form a circulation. The intubation type uses a bent pipe as the return pipe. This structure has good craftsmanship, but because the pipe protrudes outside the nut, the radial size is larger—spiral groove type, which mills a spiral groove on the outer circle of the nut. Through holes are drilled at both ends of the track and are tangent to the threaded raceway to form a return channel. This structure has a smaller radial size than the intubated structure but has a smaller radial dimension than the intubated structure. Manufacturing is more complicated. The external circulation ball screw has a simple outer circulation structure and manufacturing process and is widely used. The disadvantage is that it is difficult to make the raceway joints smooth, which affects the stability of the ball raceway.

2) Internal circulation:

The internal circulation uses a reverser to realize ball circulation. There are two types of reversers. The cylindrical convex key reverser has a cylindrical part embedded in the nut and a reverse groove 2 at the end. The reverse groove is positioned by the round key 1 on the outer surface of the cylinder and its upper end to ensure alignment with the direction of the threaded raceway. Oblate insert reverser: the reverser is a general round-headed flat key insert. The insert is embedded in the nut groove, with a reverse groove 3 at its end, which is positioned by the outer contour of the insert. Comparing the two reversers, the latter is smaller, thereby reducing the radial size of the nut and shortening the axial size. However, the outer contour of this reverser and the dimensional accuracy of the grooves on the nut require relatively high accuracy.

Ball Screw Features

1. Low friction loss and high transmission efficiency

Because there are many balls rolling between the screw shaft and the screw nut of the ball screw pair, a higher movement efficiency can be achieved. Compared with the sliding screw pair in the past, the driving torque is less than 1/3, that is, the power required to achieve the same movement result is 1/3 of that of the sliding screw pair. It is very helpful in saving electricity.

2. High precision

Ball screw pairs are generally produced continuously using the world's highest level of mechanical equipment. In particular, in the factory environment of grinding, assembly, and inspection processes, the temperature and humidity are strictly controlled. Due to the perfect quality management system, the accuracy can be fully guaranteed.

3. High-speed feeding and micro-feeding are possible

Because the ball screw pair uses ball movement, the starting torque is extremely small, and there will be no creeping phenomenon like sliding movement, which can ensure accurate micro-feeding.

4. High axial rigidity

The ball screw pair can be preloaded. The preload can make the axial clearance reach a negative value, thereby obtaining a higher rigidity (the ball screw is pressurized by the balls. When it is actually used in mechanical devices, the repulsive force of the balls can enhance the rigidity of the nut).

5. It cannot be self-locking and has reversibility of transmission

Calculation of high-precision ball screws (load-carrying capacity)

The load-bearing capacity of a high-precision ball screw refers to the maximum load it can withstand. In practical applications, the load-bearing capacity of the ball screw needs to be calculated based on specific working conditions and mechanical equipment requirements to ensure its normal operation and service life. Several common methods for calculating the load-carrying capacity of high-precision ball screws will be introduced below.

Dynamic load method

The dynamic load method is a common method for calculating the bearing capacity of ball screws. The basic principle is to calculate the load-bearing capacity of the ball screw based on working conditions and workload. Specifically, factors such as the ball screw's dynamic load rating, axial stiffness, and radial stiffness need to be considered, and the load-bearing capacity of the ball screw is calculated based on these factors.

Equivalent load method

The equivalent load method is another common method for calculating the bearing capacity of ball screws. The basic principle is to calculate the shaft life.

The life calculation of the ball screw is based on the basic load rating life of the ball screw. According to the ISO281 standard, rated life means that under normal load, 90% of the same type of ball screw can survive within the specified service life without serious quality problems such as surface damage or ball detachment. Rated life is expressed in hours or cycles. According to the ISO281 standard, the calculation formula for the rated life of the ball screw is as follows:

Lh=(C/P)^3×10^6÷(60×n)

Among them, Lh is the rated life in hours; C is the basic dynamic load in N; P is the equivalent dynamic load in N; n is the rotation speed in r/min.

Ball Screw Selection

1. Screw shaft diameter

Typical specifications are (unit: mm): 8, 10, 12, 14, 15, 20, 25, 32. Generally, the larger the shaft diameter, the greater the load.

The load that screws with different shaft diameters can be viewed in the manufacturer's catalog. The relevant parameters are dynamic-rated load and static-rated load. The static rated load refers to the rated burden that the screw can bear in a dormant state, but we cannot keep it stationary with the screw, so here, we only care about the dynamic rated load. Then, the smaller the ratio between the actual load and the rated load, the longer the theoretical life of the screw. (Note: The rated load does not represent the maximum load, but generally, it should not exceed the rated load. Otherwise it will reduce the service life of the screw)

2. Lead

Lead refers to the distance the nut moves linearly when the screw rotates once (many engineers don't know this, so mark it carefully). Common leads are (unit: mm): 2, 4, 5, 8, 10, 20, 25, 32. It is important to mention here that there is no special relationship between lead and axial clearance. The size of the lead is determined by the linear speed of the transmission.

3. Accuracy

Ball screws, according to domestic classification, have precision grades of P1, P2, P3, P4, P5, P7, and P10. Japan, South Korea, and Taiwan Province of China adopted JIS grades, namely C0, C1, C2, C3, C5, and C7. , C10; the standards of European countries adopt IT0, IT1, IT2, IT3, IT4, IT5, IT7, IT10.

Generally, our company purchases ball screws from Taiwan, which are more cost-effective, followed by those from Japan.

The accuracy is expressed as follows: No matter how long your ball screw is, if you pick a section of 300mm, the error will be within the accuracy represented by the grade. The accuracy represented by each grade is as follows:

| Accuracy level | C0 | C1 | C2 | C3 | C5 | C7 | C10 |

| Accuracy(E300) (um) | 3.5 | 5 | 7 | 8 | 18 | 50 | 210 |

Generally speaking, ordinary machinery adopts C7, C10 level, CNC equipment generally adopts C5, C3 level (C5 is more, most domestic CNC machine tools are C5 level), aviation manufacturing equipment, precision projection and three-coordinate measuring equipment generally use C3, C2 accuracy (as far as I know, ball screws above C3 are not available in the domestic civilian market).

In addition, grades C7 and C10 are generally manufactured by rolling methods, and grades C5 and above are manufactured by grinding processes.

To sum up, the accuracy grade of ball screws commonly used in non-standard designs is C7 (manufactured by rolling method or some people call it transformation), while those with higher requirements on the accuracy grade of ball screws are C5 (manufactured by grinding process). It's enough.

4. Preload level

It is also called preloading. Regarding preloading, we do not need to know the specific preloading force and preloading method. We only need to select the preloading level according to the manufacturer's sample. The higher the preload level, the tighter the nut and screw fit; conversely, the lower the level, the looser the fit (this is very important in the SCARA robot application industry, as the load will affect the preload, thereby affecting accuracy).

The principles to be followed are large diameter, double nuts, high precision, and large driving torque. When the above situations occur in the application of the screw, the preload level can be selected higher. Otherwise, the preload level can be selected lower.

The following is an introduction to how to select a screw rod:

First step, is to determine the type of screw that is suitable for your working conditions based on the application scenarios of the various screws mentioned in the "Classification of Ball Screws" above; you can also determine the accuracy level of the screw (usually C7) and Preload level;

Second step, is to determine the shaft diameter of the ball screw according to the size of the load;

Third step, is to determine the lead according to the moving speed required by the load; after selecting the lead, determine the torque to be provided by the drive motor based on the relationship between thrust and lead.

Details as follows:

The object moves vertically up and down, the weight is 60, and the required moving speed is 1m/s;

1) If you choose a servo motor as the drive and the rated speed is 3000r/min=50r/s, according to the formula v=r*i, determine the lead to be 20;

2) Then calculate the size of the load: Assume that the acceleration and deceleration time of the servo motor is set to 0.3s, then the acceleration is 3.3m/s², and the load F=600+60*3.3=798N (friction is ignored here);

3) According to the formula: F=(2*π*T*n)/i, n is taken as 90%, and T≈2.82N·m is calculated. Check that the rated torque of the 1KW servo motor is 3.18N·m, which meets the requirements.

4) Choose an appropriate itinerary.

The above is a brief introduction to the above steps. The YIHEDA selection manual has more detailed steps. If you want to know more, please get in touch with us

For a more complete guide to selecting ball screws, read: 9 Tips for Choosing Ball Screws

Installation Methods of Ball Screw

There are three main types of typical applications of ball screws:

1. One end is fixed, and the other is supported. This is the most common installation method, suitable for medium-speed to high-speed rotation, and the accuracy level can reach medium precision and high precision;

2. Fixed at both ends, only suitable for medium-speed rotation and with high precision;

3. One end is fixed, and the other is free, suitable for low-speed rotation and medium precision.

In the Yiheda selection manual, you can see the specific models and installation methods, which are very practical.

Precautions for Using Ball Screw

1. When installing, be careful not to damage the tooth surface of the screw; after the screw is purchased, the nut and screw are together, so when installing, pay special attention. First, at both ends. Tie a tie or install a limit block. Do not separate the nut and screw. Once separated, it will be challenging to install them. If it is accidentally separated, do not force yourself to install it. You can contact the supplier and ask them to install it;

2. Lubrication: There is metal friction between the ball and the screw, so lubricating oil or grease must be added between the two. Otherwise, the service life will be reduced; the general adding methods include manual and automatic refueling. Manual refueling is performed regularly by workers. Oil filling and automatic oiling require an automatic oiling system;

3. Dustproof: Ball screws are the same as rolling bearings. When mixed with debris, water, or cutting fluid, the wear will increase, sometimes leading to damage. When designing, pay attention to the dustproof ness of the screw;

4. When the eccentric load phenomenon occurs, it will directly affect the life and noise of the screw and is accompanied by a rough operating feel. If the smoothness of the screw is different when it is unloaded and after assembly, in addition to paying attention to the accuracy of the screw itself, most of them is the phenomenon of eccentric load caused by poor combination accuracy, as shown in the figure below:

5. The shortcomings of the screw are also very obvious. It cannot be self-locking and has reversibility of transmission.

For more product tips about ball screws, you could visit Tips: Learn About Ball Screw Product Knowledge learn more.

Common Problems with Ball Screws

In the field of precision mechanical transmission, the clearance problem of ball screw systems is a key technical challenge, which directly affects the positioning accuracy and operating stability of the system.

Excessive clearance may be caused by a variety of factors, including insufficient preload, excessive torsional displacement caused by unreasonable structural design, insufficient rigidity caused by improper material selection or insufficient support, and improper bearing selection and installation.

To solve these problems, engineers must apply appropriate preload to reduce or eliminate clearance, optimize structural design to enhance rigidity, and select suitable bearings to ensure precise fit. In addition, problems such as insufficient rigidity of nut seats or bearing seats, loosening of components due to vibration or lack of locking pins, and loosening of nut fixing screws also need to be solved by enhancing structural rigidity and ensuring correct tightening measures.

In terms of processing and maintenance, it is necessary to control the surface roughness of the thread, ensure the roundness and dimensional accuracy of the steel ball and thread, and prevent foreign matter from entering the steel ball track to avoid overtravel and return pipe damage. For the problem of ball screw shoulder fracture, reasonable design, precise installation and reduction of radial force and cyclic stress are the key. Through these comprehensive measures, the performance and reliability of the ball screw system can be significantly improved, providing strong support for industrial automation.

Read more: Common Problems with Ball Screws: Causes, Analysis, and Solutions

Ball Screw Inspection and Repair

The faults caused by ball screws are diverse and there is no fixed pattern. Some faults are gradual faults, which have a development process and become more and more serious with the increase of use time; sometimes they are sudden faults, which generally have no obvious signs and occur suddenly. This kind of fault is caused by various unfavorable factors and the outside world. Therefore, determining the real cause of the fault through correct detection is the premise of fast and accurate repair.

1) Inspection and repair of the clearance of ball screw nut pair and support system

When the CNC machine tool has large reverse error, unstable positioning accuracy, and knife marks appearing in the quadrant, the first thing to do is to check whether there is any clearance in the screw system. The detection methods are: use a dial indicator with a steel ball placed in the center hole at one end of the screw to measure the axial movement of the screw, and another dial indicator to measure the movement of the workbench. Rotate the screw forward and backward, observe the values reflected on the two dial indicators, and confirm the fault location according to the different changes in the values.

a) Detection and repair of the clearance of the screw support bearing

If the pointer of the dial indicator measuring the screw does not swing when the screw rotates forward and backward, it means that the screw has no movement. If the pointer of the dial indicator swings, it means that the screw has movement. The difference between the maximum and minimum measurement values of the dial indicator is the distance of the axial movement of the screw. At this time, we need to check whether the back cap of the support bearing is locked, whether the support bearing has worn out and failed, and whether the preload bearing gasket is suitable. If there is no problem with the bearing, just re-match the preload gasket. If the bearing is damaged, it is necessary to replace the bearing, re-match the preload gasket, and then tighten the back cap. The size of the axial movement of the screw mainly depends on the accuracy of the preload gasket of the support bearing. The most ideal state of screw installation accuracy is no positive and negative clearance, and the support bearing should have an interference of about 0.02mm.

b) Detection and maintenance of the gap between the double nut pair of the ball screw

Through the inspection, if it is confirmed that the fault is not caused by the movement of the screw. Then it is necessary to consider whether there is a gap between the screw nut pair. The detection method for this situation is basically the same as the detection of screw movement. Use a dial indicator to measure the workbench connected to the nut, rotate the screw forward and backward, detect the maximum gap between the screw and the nut, and then adjust it.

The method is to adjust the thickness of the gasket, so that the left and right nuts 1 and 2 have axial displacement, thereby eliminating the gap between the ball screw nut pair and generating preload. Due to the different structures of the screw nut pair, the adjustment methods are also different, which are not listed here one by one.

c) Inspection and maintenance of single nut pair

For single nut ball screw, the gap between the screw nut pair cannot be adjusted. If the screw nut pair is detected to have a gap. First check whether the thread arc of the screw and nut has been worn. If the wear is serious, the whole set of screw nuts must be replaced.

If the wear is slight, you can replace the ball with a larger diameter to repair it. First detect the maximum gap of the screw nut pair, convert it into the increase of the ball diameter, and then select the appropriate ball to reassemble. Such maintenance is relatively complicated, takes a long time, and requires a high level of technology.

d) The gap caused by the connection between the nut flange and the workbench is not fixed properly

This problem is generally easy to be overlooked. Due to the long-term reciprocating motion of the machine tool, the screws fixing the farah plate loosen and cause a gap. When checking the screw nut gap, it is best to eliminate this fault factor first to avoid taking a detour during repair.

e) Repair of faults such as unstable movement and excessive noise of the ball screw nut pair.

The unstable movement and excessive noise of the ball screw nut pair are mostly caused by poor lubrication, but sometimes it may also be caused by the servo motor drive parameters not being adjusted properly.

2) Poor lubrication of bearings and screw nut pairs

If the machine tool generates noise and vibration during operation, after detecting that there is no problem with the mechanical transmission part, the first thing to consider is the problem of poor lubrication. After many years of operation, the automatic lubrication system of the screw nut of many machine tools is often blocked and cannot be automatically lubricated. The problem can be solved by adding high-temperature and high-speed resistant grease to the bearings and nuts. Grease can ensure the normal operation of bearings and nuts for several years.

3) Servo motor drive problem

Some machine tools generate vibration and creeping during movement. Often, there is no problem with the mechanical part, and no matter how it is adjusted, the vibration and creeping cannot be eliminated. After careful inspection, it was found that the servo motor drive gain parameters are not suitable for the actual operating conditions. After adjusting the gain parameters, vibration and creeping can be eliminated.

Ball Screw Application

Machine tools

As the core equipment of the manufacturing industry, high-precision power transmission and motion control are required, and ball screws are an ideal choice to meet this demand. In CNC machine tools, ball screws are used to drive components such as workbenches, spindles and tool holders to achieve high-speed and high-precision processing operations. Its excellent performance enables the machine to perform complex processing tasks and greatly improve productivity.

Aerospace

Ball screws also play an important role in the aerospace industry. The aerospace industry has high requirements for the accuracy and reliability of its components, and the high precision, high stiffness and low friction characteristics of ball screws make them an indispensable component in this field. It is widely used in key components such as aircraft landing gear, flight control systems, flight simulators, etc. to ensure the safe operation and efficient performance of aircraft.

Automobile manufacturing industry

Ball screws also occupy an important position in the automotive manufacturing industry. On the automobile production line, many mechanical equipment need to complete their movements quickly and accurately, and the high-speed movement and high-precision positioning capabilities of ball screws make them an ideal choice for these equipment. It is widely used in key equipment such as welding robots, painting robots, assembly lines, etc. to improve automobile production efficiency and quality. In addition, ball screws are also widely used in vehicle suspension systems, steering systems, engine control, etc., improving vehicle performance and driving experience.

Electronic equipment manufacturing

In addition to the above fields, ball screws also play an important role in the field of electronic equipment manufacturing. Automation equipment in the printed circuit board (PCB) manufacturing process requires precise linear motion control, and ball screws can provide stable and precise positioning solutions. Single-axis robots are composed of ball screws and U-shaped guide rails. The characteristics of this combination battery include high mechanical stiffness and structural stability, which can achieve long single-dimensional stroke and large load. It is widely used in precision machinery, semiconductor equipment, and other equipment that requires precise positioning.

Ball screws also play an important role in logistics conveying systems, packaging machinery, textile equipment, injection molding machinery, robots, etc. The equipment in these fields needs to perform motion control tasks quickly and accurately, and the characteristics of ball screws ensure that the equipment works smoothly and efficiently, thereby improving productivity.

Ball screws play an important role in many industries such as machine tool manufacturing, aerospace, automobile manufacturing, and electronic equipment manufacturing. Its high precision, high rigidity and low friction make it the preferred transmission element in many industrial fields. With the continuous advancement of science and technology, the application of ball screws in more fields will continue to expand, providing strong support for the development of various industries. Whether in manufacturing, aerospace, automobile, electronic equipment or automation industry, ball screws will continue to play an irreplaceable role.

Difference Trapezoidal Screw vs. Ball Screw

In the field of precision mechanical transmission, trapezoidal screws and ball screws each have their own merits. The trapezoidal screw is suitable for low-speed and high-torque applications due to its simple structure and economical cost. However, due to its high friction coefficient, its transmission efficiency and accuracy are relatively low.

The ball screw, by virtue of its ball bearing and rolling friction principle, significantly reduces friction, improves transmission efficiency and positioning accuracy, and is especially suitable for high-speed and precision control application scenarios. When selecting a transmission device, engineers need to comprehensively consider the system's accuracy requirements, load-bearing capacity, service life and cost-effectiveness to ensure the optimal design of the transmission system.

With the advancement of technology, ball screws are becoming more and more popular in industrial automation and precision manufacturing due to their excellent performance, while ladder screws remain competitive in specific fields due to their economy. Proper selection of transmissions is critical to improving the overall performance and reliability of your mechanical system.

For specific information on the difference between trapezoidal screws and ball screws, view the article: Trapezoidal screws and ball screws: What is the difference?

Conclusion

Choosing the right type of ball screw depends on a variety of factors, such as load capacity, accuracy requirements and environmental conditions. Understanding the different types of ball screws on the market will help you make an informed decision and choose the right one for your specific needs.