Precision seamless flat belts are mainly used in OA equipment, financial machines, computer peripherals, and the field of automated machinery for the precise conveyance of paper, bills, cards, etc., with characteristics of accurate transmission, low rotational deviation, and low vibration.

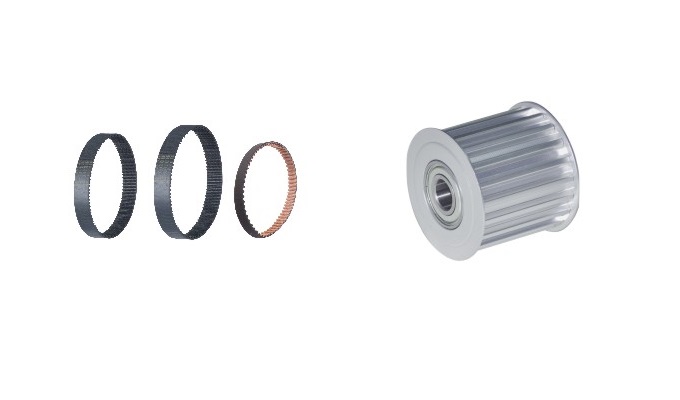

I. Cross-Sectional Structure Diagrams of Seamless Flat Belts

Two commonly used cross-sectional structure diagrams

II. Characteristics of Flat Belts

1. Excellent elasticity, allowing easy installation and removal even in complex mechanical structures.

2. Thin, seamless, flexible, and strong in bending, suitable for small pulleys.

3. Smooth operation: seamless core ensures smooth and vibration-free operation.

4. No need for re-tensioning; the N series from Nida and the E series from Bandoh are commonly used in my daily designs, both recommending an elongation rate of 5-8% (standard is 5%).

III. Design Process of Flat Belts

1. Determine shaft spacing and pulley diameters based on structural design requirements.

2. Calculate pulley diameter combinations, confirm driving pulley, driven pulley, and idler pulley.

3. Calculate the required belt length.

4. Select the closest standard belt length from the standard belt size table.

5. Fine-tune shaft spacing to match the length of the selected standard belt.

6. If adjusting the design drawing cannot meet the length of the standard belt, consider whether to create a new mold (considering the high cost and longer delivery time).

7. After selecting the belt design dimensions, calculate the design power.

8. Calculate the basic transmission capacity.

9. Check if the designed belt width is greater than the minimum belt width required for transmission.

IV. Design Considerations for Flat Belts

1. Minimum adjustment range of shaft spacing.

To install and adjust belt tension, a shaft spacing tensioning device is needed in the design.

Based on the belt length, ensure the installation space of the inner belt (Ci) or the adjustment tension of the outer side (Cs) for idler pulleys at a suitable position.

PS: For small belt sizes, a belt tensioning device may not be necessary.

|

Minimum Adjustment Range of Shaft Spacing Unit: mm |

||

|

Belt Size |

Adjustment Inward (Ci) |

Adjustment Outward (Cs) |

|

Below 500 mm |

2 mm |

4 mm |

|

500~1000 mm |

4 mm |

8 mm |

|

1000~1500 mm |

8 mm |

12 mm |

|

1500~2000 mm |

10 mm |

15 mm |

|

2000~2500 mm |

12 mm |

18 mm |

|

Above 2500 mm |

Belt circumference X 0.8% |

Belt circumference X 1% |

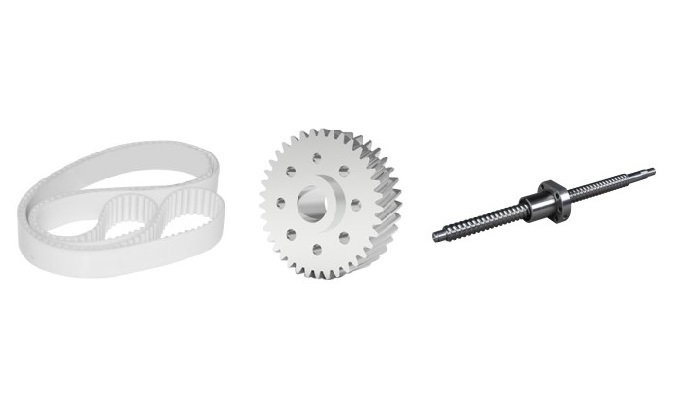

2. Design considerations for flat belt pulleys

Radius of curvature

bp:Belt pulley width, b:Belt width;hc:Crown height of the pulley, do:Outer diameter of the belt pulley, R:Radius of curvature

Belt pulley crown height: Obtain from the supplier's specifications corresponding to the belt specifications provided in curves or tables.

Belt pulley width: bp=1.1×b+5(mm)

Radius of curvature on the surface of the belt pulley (R): R = bp2 ÷ 8hc(mm)

Shape of the belt pulley: Use a symmetrical wheel shape as shown in the right image.

PS: For belt pulleys, do not set flanges or baffles on both sides, as belt wear or even breakage may occur due to collisions with flanges.

3. Safety cover

During design, try to design a safety cover for the belt to prevent foreign objects from embedding and causing belt damage or accidents. It should not be completely enclosed, and good ventilation conditions should be maintained to prevent temperature rise and reduce the belt's service life.

V. Precautions for Using Flat Belts

1. Environmental conditions

The operating temperature of the belt should be controlled within the recommended temperature range. Using it below the minimum operating temperature will cause the belt to harden, while using it above the maximum operating temperature will reduce the belt's service life. Avoid use in environments with oil, drugs, solvents, etc.

2. Alignment of belt pulley shafts

Misalignment (parallelism, eccentricity) of belt pulley shafts can cause belt meandering or slipping off the pulley, resulting in damage. Therefore, control the alignment of the belt pulley shaft within the range specified in the belt specification sheet.