Rack and pinion, timing belt and lead screw are three common transmission methods, each with its own unique advantages and disadvantages. The following is a detailed analysis of the advantages and disadvantages of these three transmission methods:

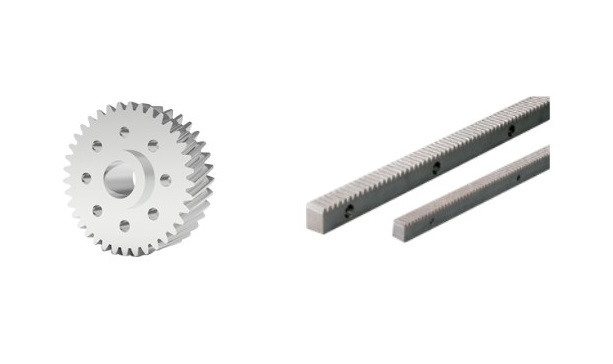

Gear & Rack

Advantage:

a. Accurate transmission and high precision, up to 0.1mm, suitable for high-precision transmission requirements.

b. The transmission is stable, the speed changes little, can transmit large torque, can be connected to an infinite length, and the transmission speed can be very high, >2m/s.

c. Compact structure, suitable for long-distance transmission.

d. Has a high load-bearing capacity.

Disadvantages:

a. The manufacturing and installation accuracy requirements are high and the cost is high.

b. During the working process, if there is a large error in the transmission system, large noise will be generated.

c. Maintenance and replacement of gear racks require professional operations and are difficult to operate.

Applications:

It is mainly used in large-format steel plates, glass CNC cutting machines, construction elevators and other equipment that can reach a height of 30 stories.

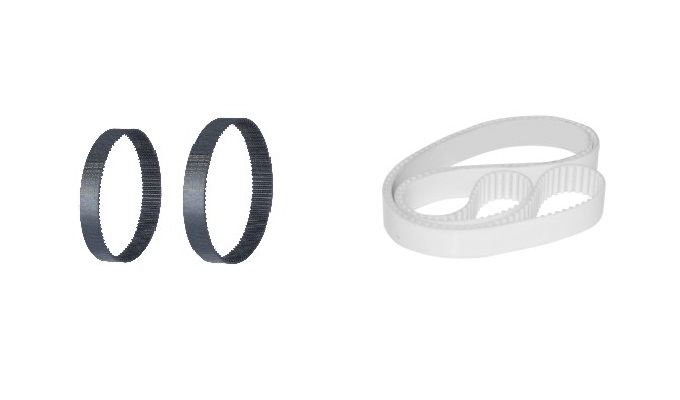

Timing belt

Advantage:

a. The transmission is smooth, the precision is high, and it is suitable for high-speed transmission.

b. It has good anti-vibration performance and can absorb a certain amount of vibration.

c. It has good adaptability to corrosion and high temperature environments.

Disadvantages:

a. The synchronous belt has a short life and is easy to wear and needs to be replaced frequently.

b. A special tensioning device is required to maintain the tension of the timing belt.

c. For high-speed transmission, the synchronous belt needs to withstand large centrifugal force, which can easily cause wear of the pulley.

Applications:

It is often used in linear motion control systems that require high precision, high speed and small transmission distance, such as printers, CNC machine tools, etc. It can also be used for short-distance transmission from servo motor to transmission gear or servo motor to lead screw.

Lead screw

Advantage:

a. Simple structure, easy to operate, suitable for various mechanical equipment.

b. Able to convert rotational motion into linear motion, or linear motion into rotational motion.

c. It has good adaptability to high strength and high stiffness transmission requirements.

Disadvantages:

a. Under high load conditions, the screw is prone to greater friction and wear and requires regular maintenance and replacement.

b. For high temperature and corrosive environments, the life of the screw will be greatly shortened.

c. The manufacturing and installation accuracy of the screw is high and the cost is high.

Applications:

It is a device that converts rotary motion into linear motion, usually consisting of a threaded screw rod and a nut. It is widely used in various mechanical equipment, such as cranes, stamping machine tools, etc. It has the characteristics of large transmission distance and strong load-bearing capacity.

In summary

The three transmission methods of rack and pinion, timing belt and lead screw have their own advantages and disadvantages. The choice of which transmission method to use needs to be decided based on the actual working environment and application requirements.