What is a Oil Free Bushing Copper Alloy?

Copper alloy oil free bushings are a kind of self-lubricating bearings made by using high-strength brass as the base material and adding the appropriate amount of graphite as the lubricating material. Their main feature is that they have good self-lubricating properties and can operate stably over various temperatures and loads without needing additional lubrication. This material performs well in friction and wear and has a long service life and low maintenance cost. Copper alloy oil-free bushings are widely used in various mechanical equipment, such as bearings, gears, reducers, etc.

Understanding the Composition of Copper Oil Free Bushings

The main components of oil-free bushings copper alloy include the base and lubricating materials. Among them, the base material is high-strength brass (SP2), which has high hardness and strength and can provide sufficient support and wear resistance, as well as good processing performance and corrosion resistance. The lubricating material is mainly graphite, which has good lubricating properties and can form a lubricating film to reduce friction and wear, reduce noise and prolong service life.

In addition, copper alloy oilless bushings may add some other materials, such as enhancers, antioxidants, etc., to improve their performance and service life. Among them, the reinforcing agent can enhance its mechanical properties and wear resistance, and the antioxidant can improve its corrosion and anti-aging properties.

Oil free bush copper alloy is a multi-component material. Its composition mainly consists of high-strength brass and graphite, while other materials may be added to improve its performance and service life.

Oil Free Bushings used in Different Occasions

Oil free bushings and copper alloy straight are suitable for compound movements in various mechanical equipment. In particular, copper alloy oil free bushes show excellent performance in various compound movements such as relatively heavy load and low speed or linear rotation. For example, in heavy equipment in metallurgy, chemical industry, machinery manufacturing, and other industries, copper alloy oil-free bushings are widely used in bearings, gears, reducers, slides, and other components to provide good friction performance and stable operation.

In addition, copper alloy oilless bushings can be used on special occasions, such as high temperature, high pressure, strong corrosion, and other environments. On these special occasions, the self-lubricating performance of copper alloy oil-free bushings can reduce the use of additional lubricants, thus improving the safety and stability of the equipment. At the same time, the wear and corrosion resistance of copper alloy oil-free bushings can also extend the service life of the equipment. Copper alloy oil-free bushings are widely used in various machinery and equipment, especially for applications subjected to relatively heavy loads and low speed or linear rotation and other compound movements.

Copper Oil Free Bushing Product Features

Copper alloy oil free bushings have many unique product features that make them widely used in various industrial fields, including but not limited to the following:

1) Low maintenance frequency: Oil free bushings copper alloy are self-lubricating and do not require additional lubricants, thus reducing the frequency of maintenance and servicing.

2) High load bearing and impact resistance: Oilless bushings have high strength and hardness, which can withstand large pressure and impact, thus improving the stability and safety of the equipment.

3)Thin bushing thickness and compact structure design: Oil free bushing copper alloy has a thin bushing thickness and compact structure design, which reduces the equipment's occupied space and improves the equipment's operation efficiency.

(4) Can be used for both linear motion and rotary motion, and other compound motion: Copper alloy oilless bushings are suitable for various compound motion occasions, such as linear motion, rotary motion, etc., with good adaptability and stability.

(5) Applicable to "high temperature," "low temperature" severe temperature conditions and liquids and other special environments: copper alloy oil-free bushings have good resistance to high temperature, low temperature, and corrosion resistance, can adapt to a variety of harsh environments, such as high temperature, low temperature, chemical liquids, etc.

The Principle of Oil Free Bushing Products Selection

Copper alloy oil free bushings are an important mechanical accessory, and selecting suitable bushings is essential for the equipment's stable operation and extended service life. When choosing oil free bush, the following principles should be considered:

Use environment: The working temperature, load, operating speed, frequency of use, and the need for refueling of the equipment need to be considered. According to these factors, choose the appropriate copper alloy oil-free bushing material, type, and specification size.

Select the bushing specification size and shape: The appropriate bushing specification size and shape should be selected according to the actual needs of the equipment to ensure the precise fit between the bushing and the bearing to achieve the best friction effect and operating efficiency.

Confirm the bearing service life and reliability requirements: The equipment's bearing service life and reliability requirements need to be confirmed to select the suitable copper alloy oil free bushings. Selecting high quality oil free bushings can effectively improve the stability and safety of the equipment and extend its service life.

Fully understand the characteristics and performance of copper alloy oil free bush: Before choosing oil free bushings copper alloy, you should fully understand the characteristics and performance of copper alloy oil free bushings, including their wear resistance, corrosion resistance, and load-bearing capacity. According to the actual needs of the equipment, choose the appropriate oil free bush material and model to ensure the normal operation of the equipment.

Copper Alloy Oil-free Bushing Product Installation

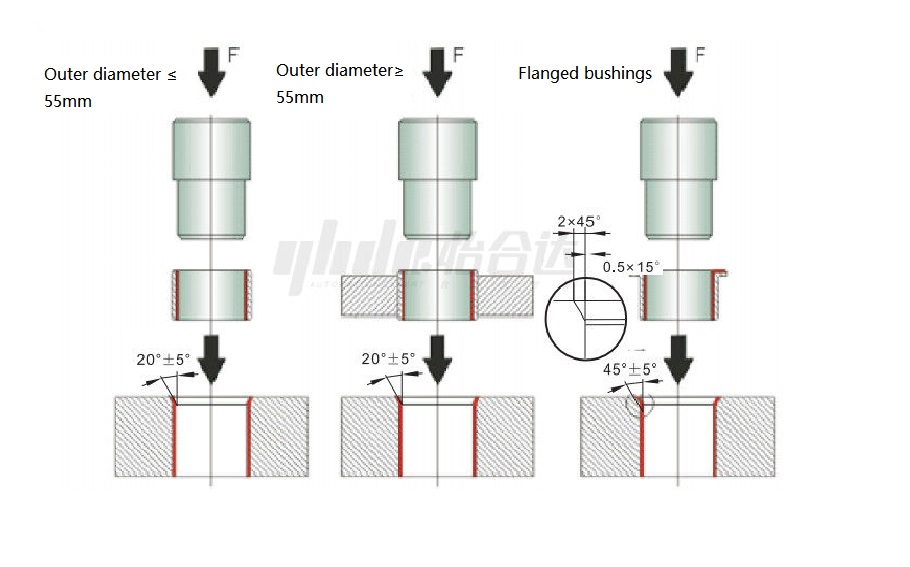

Proper installation of oil-free bushings copper alloy is an important step to ensure stable operation and longer equipment service life. The following are the installation principles and steps for oil-free bushings:

Clean before assembly: Before installation, the bushing and seating bore surfaces should be carefully cleaned to ensure they are free of any impurities. The surface of the seat bore should be as clean as possible to avoid scratching during assembly.

Use lubricant: During assembly, a small amount of lubricant can be properly applied to the outer surface of the bushing to reduce friction and facilitate the assembly of the bushing. It is recommended that the jig be pressed in slowly (hydraulic press or bench vise is recommended), and direct knocking of the bushing is prohibited to avoid deformation.

Screw fixing: For high load-bearing, reciprocating motion, it is recommended to use screws to fix the bushings on the seat holes. It helps to ensure the stability and safety of the bushing.

Pay attention to the order and direction of assembly: When installing the bushings, they should be assembled correctly. Incorrect installation may damage the bushing or failure of the equipment from operating properly.

Confirm the quality of installation: After completing the installation, the bushing should be checked to ensure it is properly installed, firm, and stable. If any problem occurs, it should be solved immediately to ensure the normal operation of the equipment.

In conclusion, proper installation of copper alloy oil-free bushings is essential for stable operation and long service life of the equipment. Before installation, it should be carefully cleaned and lubricated, pay attention to the assembly sequence and direction, and confirm the installation quality to ensure the normal operation of the equipment.

Product Maintenance

For copper alloy oil-free bushings, maintenance work is very important. Regular refueling and lubrication is the key to keeping the bearings working properly. Suitable lubricants should be selected according to the actual situation and refueled according to the requirements. Also, the wear degree of the bearings should be checked so that they can be replaced or repaired in time. If the bearings are working abnormally or in abnormal conditions, they should be stopped and seek professional repair or replacement in time. Through scientific and reasonable maintenance, the service life of copper alloy oil-free bushings can be effectively extended, and their stability and reliability improved.

Need to take Precautions for copper alloy oil free bushing use:

◆When using copper alloy oil-free bushings, avoid using lubricating oil or grease containing hard particles to avoid damaging the surface of the bushings. It is recommended to use graphite powder or other suitable oil-free lubricating materials.

◆When processing bushings, process accuracy should be maintained to avoid problems such as over-cutting or under-cutting, which may affect bearing performance.

◆During storage and transportation, care should be taken to avoid damage or corrosion on the surface of copper alloy oil-free bushings so as not to affect their performance.

◆The surface of copper alloy oil-free bushings may produce a certain degree of wear or dent during long-term use, which is a normal phenomenon. If the bearing performance is found to drop or there is abnormal noise and other conditions, it should be inspected and replaced in time.

◆When mounting and dismounting copper alloy oil-free bushings, appropriate tools and methods should be used to avoid damage to the surface of the bushings.

◆When using copper alloy oil-free bushings, attention should be paid to the working temperature range to avoid exceeding its tolerance range. The working temperature range without oiling is -40℃ to 200℃, and the working temperature range with regular oiling is -40℃ to 150℃.

◆The inner diameter size of copper alloy oil-free bushing should be selected with suitable tolerance as needed to ensure the accuracy of its fit with the mating shaft.

For the tolerances of matching shaft of inner diameter, F7 type is recommended to choose d8 (for general use), e7 (for general use), F8 (for high precision), and G6 (for high precision, intermittent motion); the tolerances of matching shaft of inner diameter G6 type are recommended to choose g6 (for high precision).

Using Example Case

(1) Automotive industry: Copper oil-free bushings can be used in the hanger, welding tooling fixture, and other automotive assembly and conveying line components. Which has a high load-bearing capacity, high impact resistance, and low maintenance frequency, which can improve production efficiency and reduce maintenance costs.

(2) Food/medical product/cosmetic industry: Oil free bushings copper are widely used in mechanical equipment in the food, medical product, and cosmetic industries, such as labeling machines, filling machines, capping machines, packaging machines, inspection machines, weighing machines and other equipment, which can meet the requirements of high-speed and high-load movements without generating oil pollution.

(3) Factory equipment: Copper oilless bushings can be used in parts feeders, cutting machines, processing machines, assembly machines, and other components in factory equipment, which can meet the requirements of high load and high precision, and at the same time reduce maintenance costs.

(4) Logistics equipment: Oil free bushings copper can also be used in forklifts, AGV vehicles, conveyor lines, and other components in logistics equipment, which can improve the reliability and operational efficiency of the equipment.

(5) Other fields: Oilless bushings copper are also used in new energy, molds, testing equipment, industrial robots, chuck mechanisms, lifting mechanisms, various guides/links, etc., which can improve the accuracy and stability of the equipment and reduce maintenance costs.

Conclusion

Through this article, we hope we have listed some examples of copper oil free bushing use, and if you have any customized needs or want to know more about copper oil free bushing applications, please feel free to contact us. We wish we could help you.