Introduction

Oil free bushings, also known as self lubricating or oiless bushings, are bearings that do not require external lubrication to function properly. These bushings are made of materials designed to self-lubricate, such as metal polymers or composite materials, which reduces friction and wear on the bearing surfaces. The development of oil-free bushings dates back to the 1930s when the first self-lubricating bearings were introduced. However, it was not until the 1960s that the use of composite materials in bearings became prevalent. In the 1980s, the development of metal-polymer bearings, which combine the properties of metal and polymer materials, further improved the performance of oil free bushings.

Oil free bushings benefit by eliminating the need for external lubrication, which reduces maintenance costs and saves time. Additionally, these bushings do not leak oil, eliminating environmental concerns and keeping the working area clean. Oil-free bushings also operate silently, reducing noise pollution in the working environment. Oiless bushings are crucial in various industries, including aerospace, automotive, construction, medical, and manufacturing.

Today, oil-free bushings continue to evolve with new materials and designs that offer better performance and longer service life. They are essential to many industries and have revolutionized how machines and equipment are designed and maintained.

How to do oil free bushing work?

The self lubricating materials used in oilless bushings include metal polymers, composites, or other materials with inherent self-lubricating properties. These materials release a small amount of lubricant during operation, creating a thin film between the sliding surfaces of the bushing. This lubricant film reduces friction and wears on the bearing surfaces, improving performance and longevity.

In addition to self-lubricating materials, the design of oil-free bushings is also important for their function. Some designs feature grooves or pockets that retain and distribute the lubricant evenly across the sliding surfaces. In contrast, others may use a liner material that is bonded to the metal shell of the bushing to provide a low-friction surface for the sliding elements.

Overall, oil-free bushings operate with minimal friction and wear, using self-lubricating materials and clever design to ensure they remain lubricated without needing external lubrication. It makes them ideal for a wide range of applications, particularly those that require low maintenance or are challenging to access for maintenance.

Work principle of oil free bushing

After the operation, copper alloy oilless bushings typically have a solid lubricant occupying 20%-30% of the friction surface area. The lubrication principle is that some graphite particles transfer to the friction surface during the sliding friction process between the shaft and the bearing, forming a stable solid lubrication membrane that prevents direct adhesion and wear between the shaft and the bearing. While graphite has good lubricity but poor load-bearing capacity, metal has good load-bearing capacity but poor lubricity. However, embedding lubricant into a metal matrix allows oil-free bushings to have both high load-bearing capacity and good lubricity properties of graphite materials.

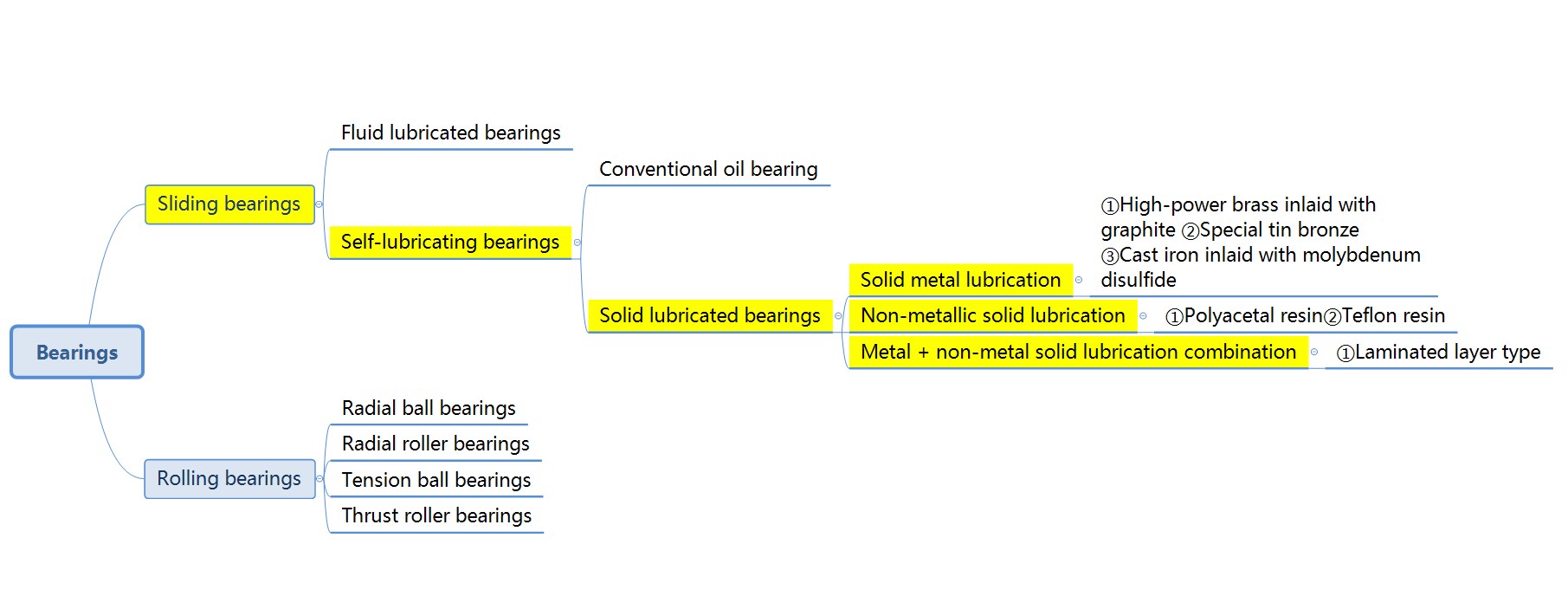

Types of Oil-Free Bushings

There are several different oil-free bushings, each with unique properties and applications. Some common types include:

Composite layer oiless bushings

Composite layer oilless bushings are compact in structure and suitable for heavy-duty, low-speed applications. They have the advantages of low production cost and high production speed, making them ideal for scenarios with high demand for batch production but low precision requirements.

Resin-based oil free bushings

Resin-based oil-free bushings are resistant to dust/dirt and produce low noise. They are suitable for low-load, low-speed applications and have the advantages of low production cost and high production speed, making them ideal for scenarios with high demand for batch production but low precision requirements.

(PTFE) oil free bushings

Polytetrafluoroethylene (PTFE) oil-free bushings are corrosion-resistant and comply with food safety laws. They have higher precision than resin-based oil-free bushings and are more suitable for low-load, high-speed applications.

Cast iron oil free bushings

Cast iron oil-free bushings have high precision and low thermal deformation and are more economical than copper alloy oil-free bushings. They are suitable for medium-load, low-speed applications.

Aluminum-plastic sliding linear bearings

Aluminum-plastic sliding linear bearings made of engineering plastics are lightweight and corrosion-resistant. They can replace rolling linear bearings and have the functions of heavy-duty use, self-lubrication, and low noise.

Oil-free bushing components

Oil-free bushing components of steel shells with copper alloy bushings or aluminum shells with composite layer bushings can greatly reduce assembly time and be more convenient. The outer shell is treated to resist corrosion and looks more attractive.

The advantages of oil free bushing

1. Simple structure to shorten the design time, easy to install and replace.

2. Self-lubrication without oil supply device, low maintenance frequency, longer life, lower cost.

3. Meet both linear and rotary motion, but frequent start and stop use in high or low temperature extreme environments.

4. Since oil-free bushings do not require lubricants, they do not pollute the environment and are more environmentally sustainable;

5. Compared with the traditional lubrication method, the use of oil-free bushings can substantially reduce noise and vibration and improve the operating stability and precision of equipment;

6. Oil-free bushings have good wear resistance and corrosion resistance, which can effectively reduce the loss and maintenance costs of equipment and improve production efficiency and economic benefits;

7. The performance of oil-free bushings is stable and reliable and can withstand large working loads and shock loads to ensure the equipment's safety, reliability, and service life.

8. Oil-free bushings are available in a wide range of materials. Suitable bushing materials can be selected according to different working conditions and environmental requirements to meet the needs of equipment operation to the maximum extent.

Applications

The excellent performance of oil free bushings has made them widely used in many industries.

In automobile manufacturing, oil free bushings can be used in engines, suspension systems, steering systems, brake systems, transmission systems, and other components to improve the durability and reliability of automobiles.

Oil-free bushings can be used in excavators, loaders, cranes, and other machinery and equipment to improve their efficiency and stability in construction machinery. In industrial robots, oil-free bushings can be used in various joints, servo drives, and other components to improve robot movement accuracy and reliability.

In the new energy field, oil-free bushings can be used in wind turbines, solar tracking systems, and other equipment to improve operational efficiency and stability. In the 3C electronic field, oil-free bushings can be used in cell phones, laptops, tablet PCs, and other devices such as keys, rotating shafts, and other components.

In addition, oil-free bushings can also be used in logistics and transportation, fitness equipment, food, and medical fields to improve the safety and reliability of equipment and reduce operating costs and maintenance expenses. In short, oil-free bushings have many applications and can play an important role in various mechanical equipment.

Conclusion

In conclusion, today's oil-free bushings offer many advantages over their traditional counterparts. Their simple structure, self-lubricating properties, ability to withstand extreme temperatures, and frequent start-stop operations make them highly versatile and ideal for use in various industries, from automotive and engineering to 3C electronics and healthcare.

By exploring the different types of oil-free bushings and selecting the one that suits your specific application needs, you can significantly improve the efficiency and reliability of your equipment while reducing maintenance costs and enhancing safety. So why not switch to oil-free bushings today and experience the benefits yourself? Please feel free to contact us today and choose the right oil free bushing for you.