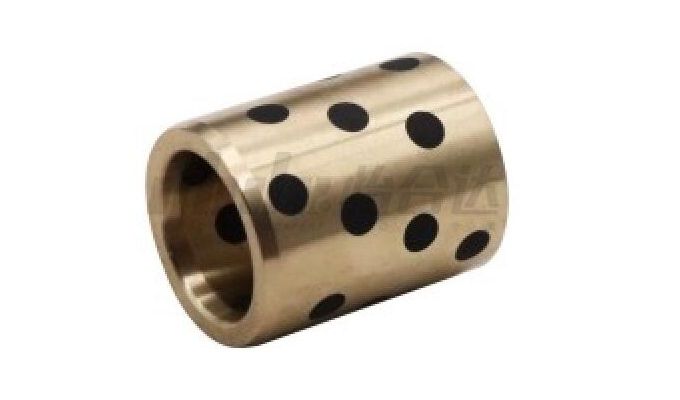

What Are Oil Free Bushings?

Oil-free bushings, also known as self-lubricating bearings, are a novel type of lubricating bearing that combines the characteristics of metal bearings with the advantages of oil-free lubrication. These bearings utilize a metal base for load-bearing capabilities, supplemented by a specialized solid lubrication material to achieve aerodynamic lubrication effects. Noteworthy for their robust load-bearing capacity, impact resistance, high-temperature endurance, and strong self-lubricating capabilities, oil-free bushings are particularly well-suited for challenging scenarios involving heavy loads, low speeds, reciprocating or oscillating movements, where traditional oil film lubrication might be inadequate. Furthermore, they can withstand water flushing, acid erosion, and other corrosive substances.

What are Advantages of Oil-Free Lubricating Bearings?

Versatile Applications: Oil-free bushings find utility in situations where adding or maintaining lubrication is difficult or impossible. This not only minimizes maintenance needs but also mitigates risks stemming from insufficient lubrication.

Elimination of Lubrication Devices: Dispensing with the requirement for continuous lubrication devices reduces installation and operational costs. The oil-free approach simplifies design and structure, resulting in cost savings and shorter design cycles.

Eco-Friendly: The absence of oil disposal reduces environmental impact, making these bearings environmentally friendly.

Reduced Material Requirements: Lower hardness requirements for shafts diminish the necessity for quenching, streamlining the production of related components.

High and Low-Temperature Resistance: Certain oil-free bushing products can endure temperatures ranging from -200°C to 600°C, exhibiting outstanding high and low-temperature performance.

What Is the Lifespan of Oil-Free Lubricating Bearings?

The lifespan of any bearing is contingent upon real-world operating conditions such as workload, velocity, temperature, and surrounding environmental factors. Manufacturers cannot accurately calculate the precise lifespan before undergoing practical validation. Instead, they rely on existing usage cases to estimate the bearings' lifespan under similar circumstances. With an extensive case repository, companies like Yiheda can assist in identifying the most suitable oil-free bushing products for specific scenarios.

What is the material composition of oil-free lubricated bearings?

Oil-free lubricating bearings primarily consist of the following materials:

Metal Materials: High-strength brass, tin bronze, and similar metals are commonly employed, often combined with graphite-bearing materials.

Porous Metal Materials: Produced using powder metallurgy techniques, these materials possess excellent lubricating properties.

Non-Metal Materials: This category encompasses materials like nylon and polytetrafluoroethylene (PTFE), which can serve as lubricating substances in certain applications.

What is the difference between oil-free bushing, conventional bearings and rotating bearings?

Oil-free lubricating bearings fall within the realm of sliding bearings. In contrast to conventional sliding bearings that necessitate the application of lubricating oil or grease to form a lubricating film, oil-free sliding bearings are either manufactured from self-lubricating materials or pre-filled with lubricant and sealed, allowing them to operate over extended periods without requiring additional lubrication.

|

Feature |

Oil-Free Bushings |

Conventional Bearings |

Rotating Bearings |

|

Lubrication |

Can be used without lubrication |

Often requires lubrication |

Typically requires lubrication |

|

Speed Capability |

Primarily for low and medium speeds |

Can operate at high speeds with lubrication |

Mainly for medium loads |

|

Load Capacity |

Suited for medium to high loads |

Can handle high loads with lubrication |

Mainly for light loads |

|

Impact Resistance |

Excellent |

Good |

Poor |

|

Dimensions |

Relatively thin wall |

Relatively thin wall |

Relatively thick wall |

|

Friction Coefficient |

Relatively high |

Can be high without lubrication |

Very low |

|

Bearing Shape |

Meets various mechanical design requirements |

Usually no limitations in current conditions |

Standard products have limitations |

|

Noise |

Relatively low noise |

Relatively low noise |

Relatively high noise |

|

High-Temperature Resistance |

Very good |

Average (significant material variation) |

Not good |

When using self-lubricating bearings, temperature rise reasons and how to solve it?

Reasons for Temperature Rise:

Cooling Interruption: Disruption in the cooling water supply for self-lubricating bearings.

Lubricant Issues: Decline in oil quality or contamination during operation, such as increased water content leading to heightened oil acidity, thereby diminishing lubrication effectiveness and raising bearing temperatures.

Resolution:

Firstly, when the temperature of self-lubricating bearings rises, it is crucial to determine if any faults exist.

In the case of elevated temperatures, the following measures can be taken:

Inspect the cooling water system to ensure proper water flow, pressure, and pipeline integrity. Low water pressure may be attributed to clogged filters.

Check the oil pressure of speed controllers. Low oil pressure could potentially close the hydraulic valve for cooling water.

Assess whether the bearings emit abnormal noises and if any irregular swinging occurs.

Extract oil samples to observe changes in oil color. Laboratory testing can confirm oil degradation. If degradation is confirmed, halt operations and replace the oil.

Examine oil labels and levels. If anomalies exist, inspect the drain valve of the oil tank for proper closure. If it's sealed, add oil; if there's leakage due to a faulty seal gasket, halt operations for repair.

What are the application of oil-free lubricated bearings?

Self-lubricating bearings find application in various domains, including:

Construction Machinery: Excavators, bulldozers, loaders, and more.

Plastics and Rubber Machinery: Injection molding machines, tire vulcanization equipment, blow molding machines, and more.

Automotive Components: Transmissions, differentials, clutches, and more.

Office Equipment and Fitness Equipment: Copiers, printers, gym equipment, and more.

Mold Guide Bushings: Guiding, inclined planes, positioning, guiding rails, and related mold components.

Food and Pharmaceutical Machinery: Rotational and reciprocating parts in machinery requiring high production environment standards.

Through the utilization of self-lubricating bearings, efficiency can be enhanced, maintenance costs reduced, and specific lubrication requirements met.