Product Introduction

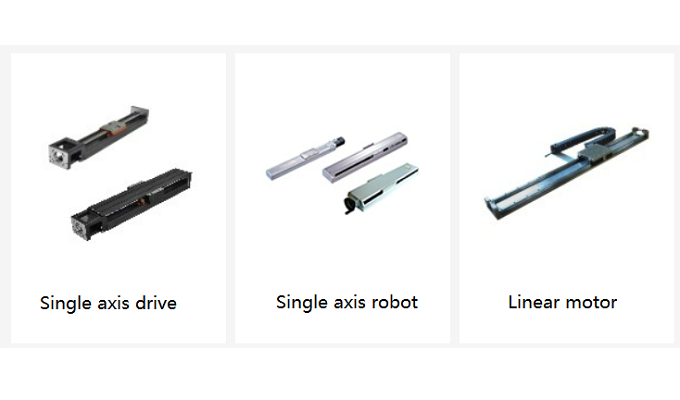

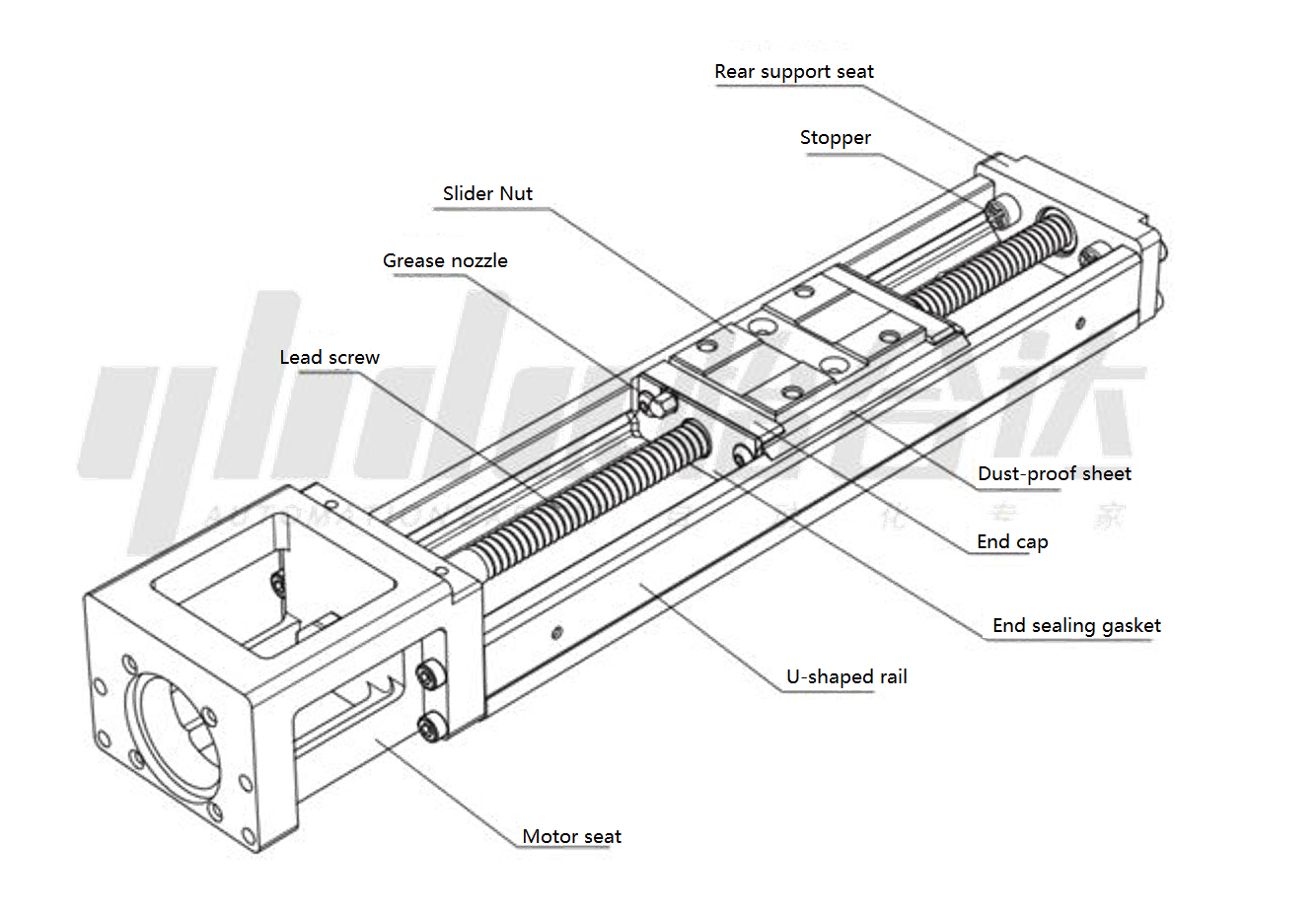

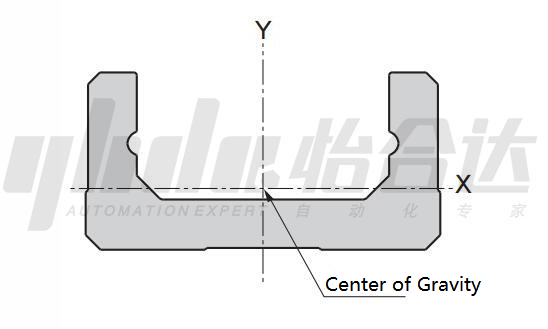

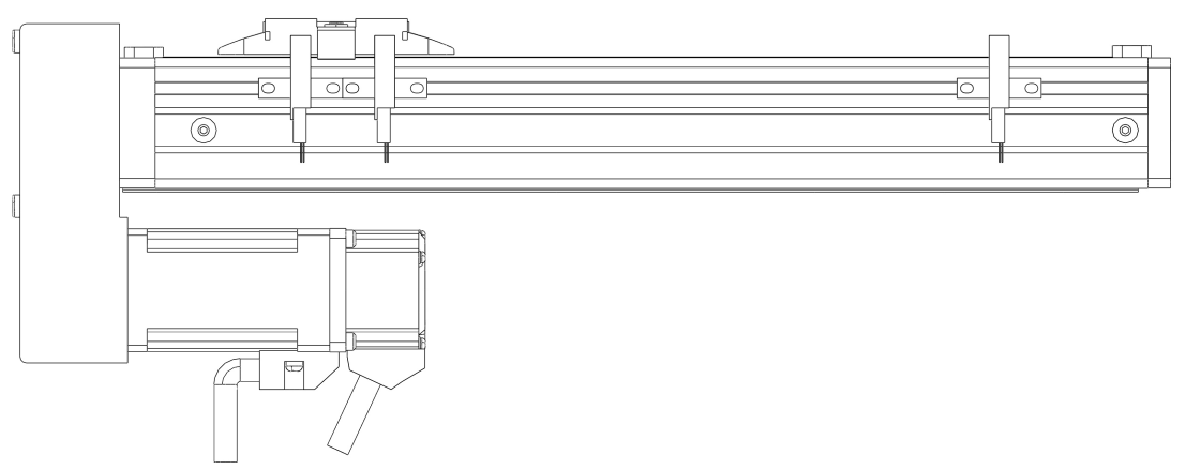

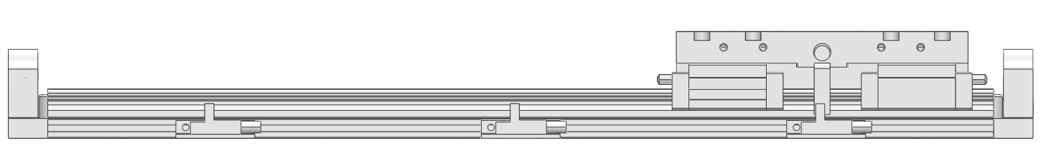

(1) The single-axis driver, through modular design, integrates the ball screw and linear guide rail. With the high-precision ball screw as the transmission mechanism and the U-shaped track groove as the guide, it realizes high-precision transmission that converts the rotation of the screw into linear motion.

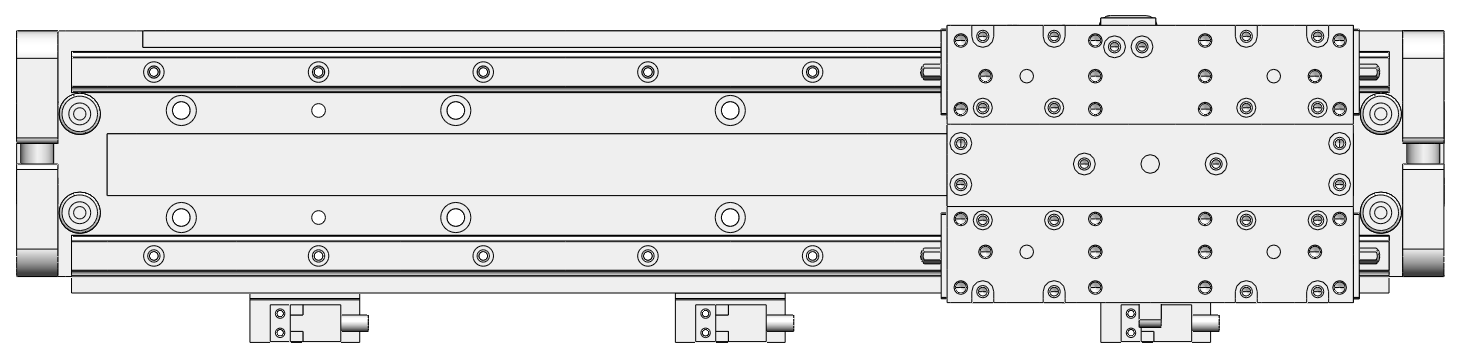

(2) The single-axis robot is also known as a linear slide, linear module, industrial manipulator, XY slide, etc. It is widely used in automated equipment and production lines in various industries, featuring specialization, standardization, and modularization. It plays an important role in improving the quality of automated equipment and reducing equipment costs. According to the different use environments, it is divided into slides used in general environments and those used in dust-free environments. According to different driving methods, it is divided into high-precision slides driven by ball screws and high-speed slides driven by timing belts.

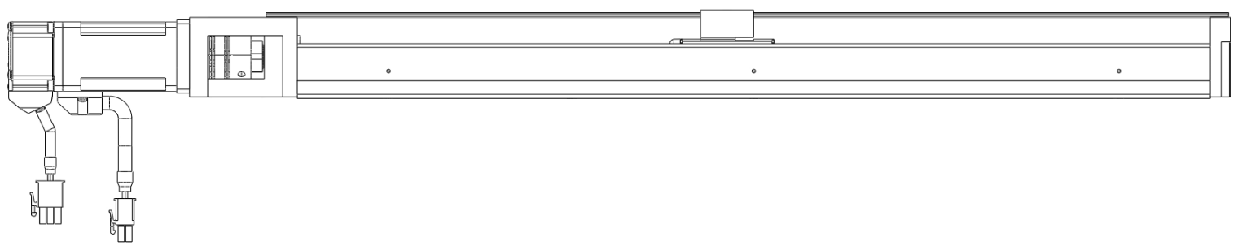

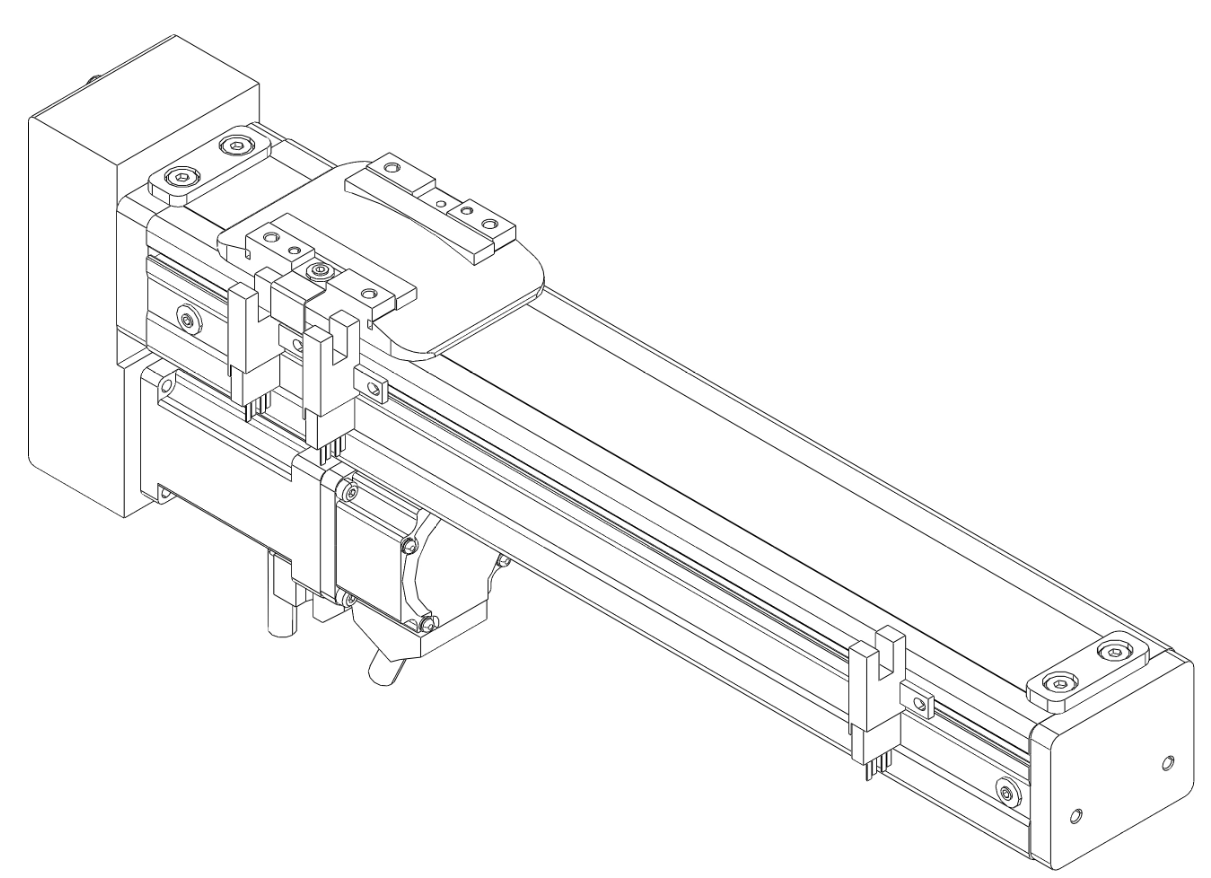

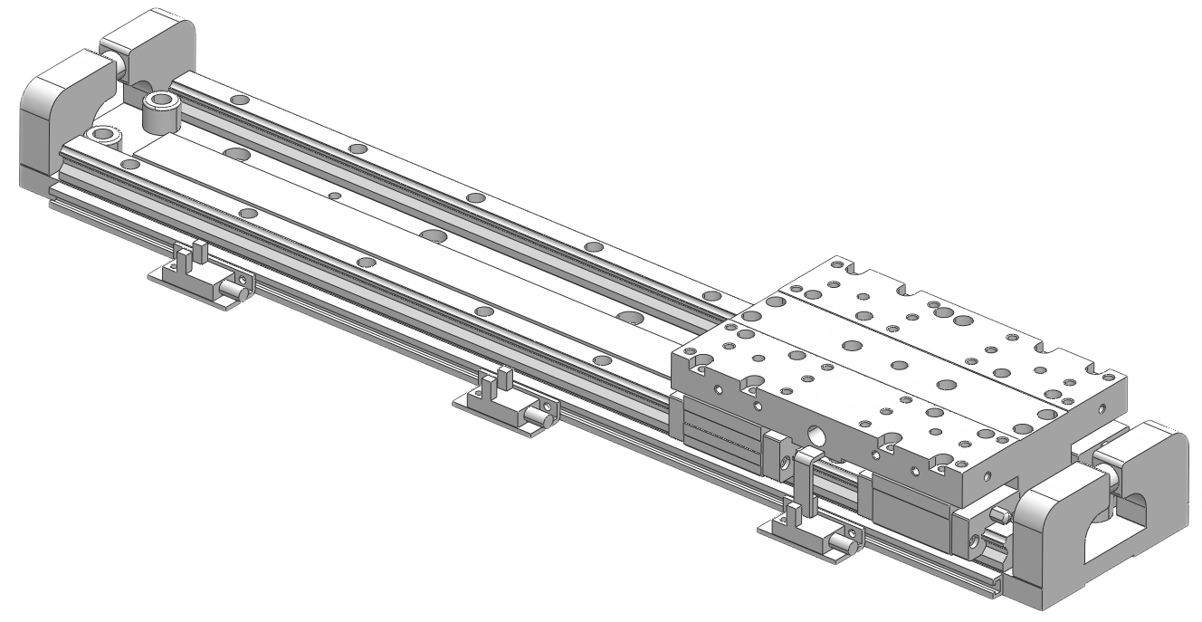

(3) The linear motor is a short-distance running expert. It can make more than fifteen round trips per second under the condition of short stroke (≤4mm) motion. It is also very suitable for long-stroke applications (1000 - >5000mm), and several movers can be installed on the same axis, increasing the flexibility of non-standard automated machine design.

You can choose servo motors or stepper motors by yourself.

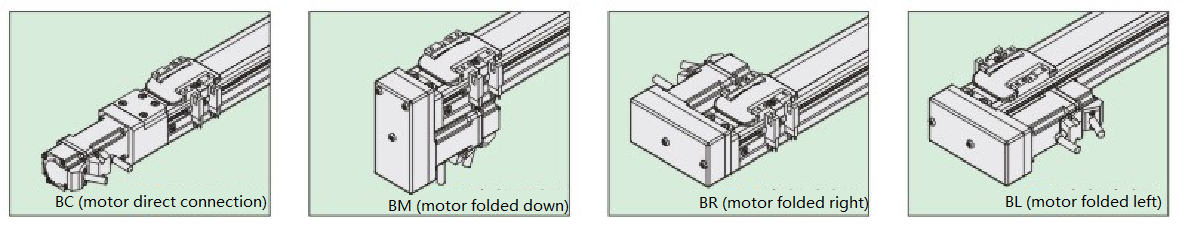

Motor connection methods: direct connection, downward folding, left folding, right folding.

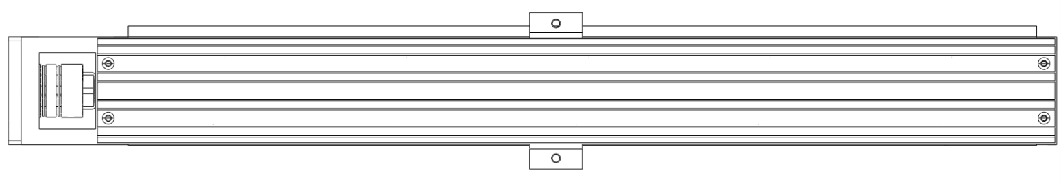

Single-axis driver

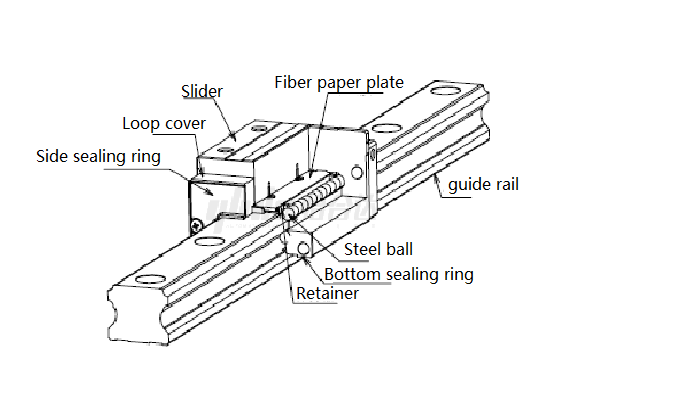

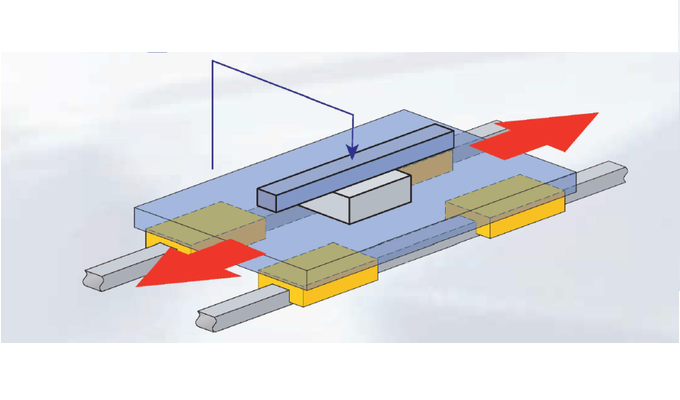

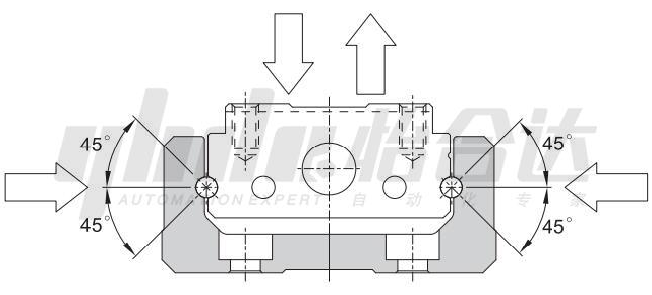

Four-direction equal load

High-rigidity

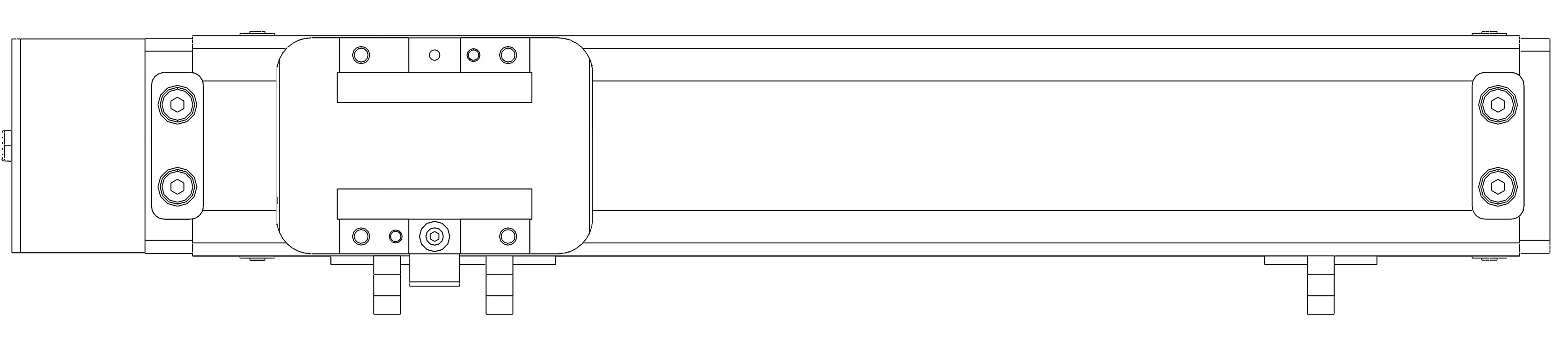

Single-axis robot

Effectively preventing dust and impurities from entering the inside of the body.

Linear motor

The linear motor has ultra-high response and ultra-high precision.

Application Industries and Cases

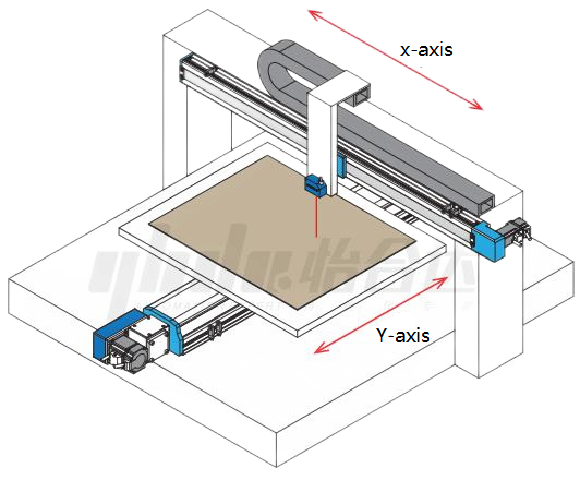

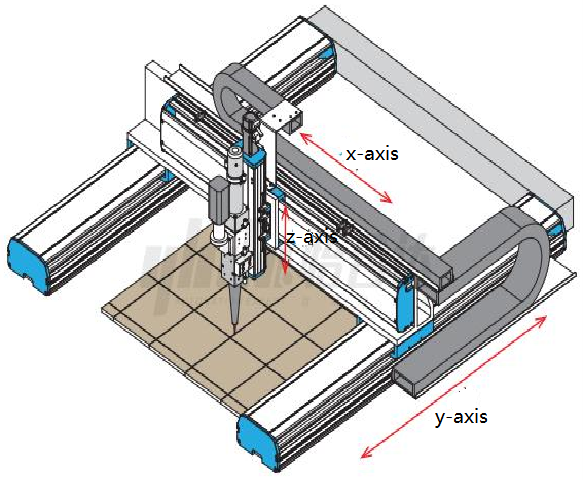

(1)Flatness Detection

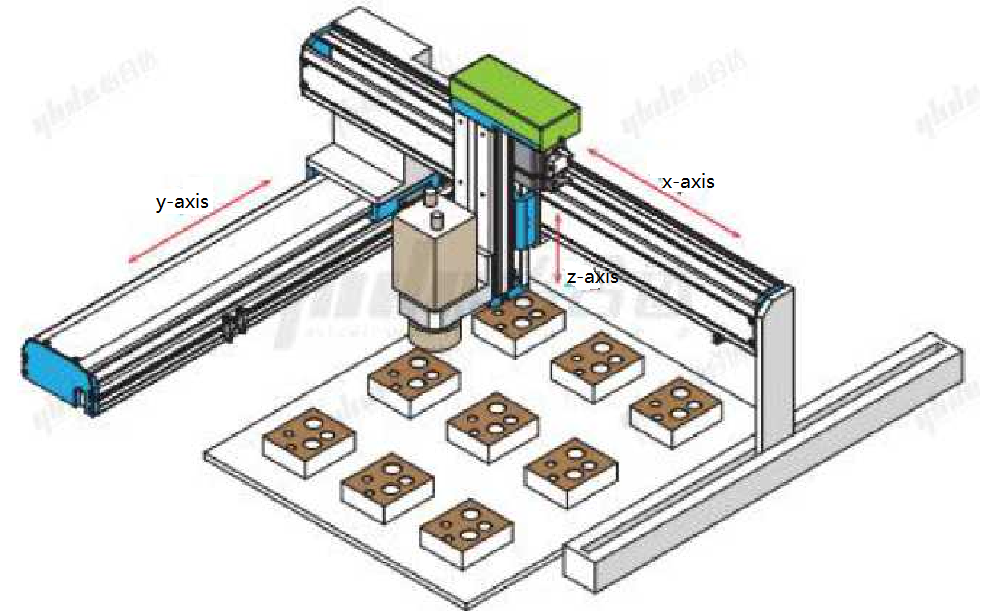

The Y-axis drives the workpiece to move back and forth, and the X-axis drives the laser ranging sensor to move left and right. The height of multiple sampling points on the workpiece surface is measured to calculate the flatness error.

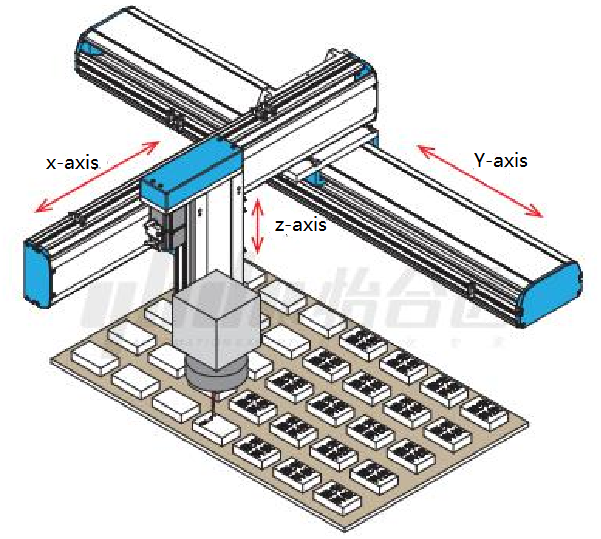

(2) Laser Cutting

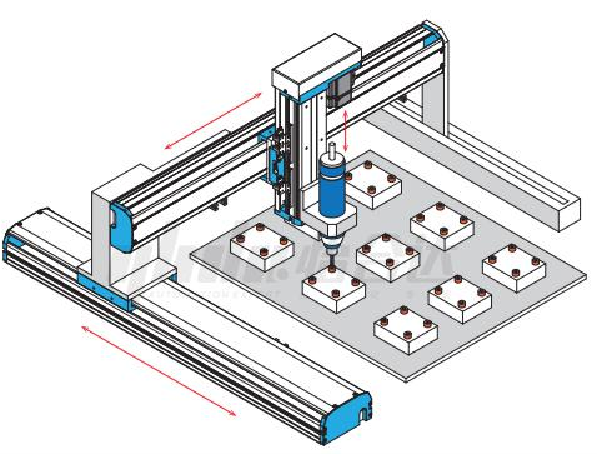

The Z-axis can be equipped with different devices to achieve a variety of operations. Equipped with a cutting tool, it can cut, equipped with a camera, it can perform visual inspection, equipped with a dispensing head, it can dispense glue, equipped with an electric screwdriver, it can lock screws.

(3) Laser Marking

The marking range of the galvanometer marking head itself is small. The X/Y-axis can expand the marking range widely, and the Z-axis can adjust the laser focus.

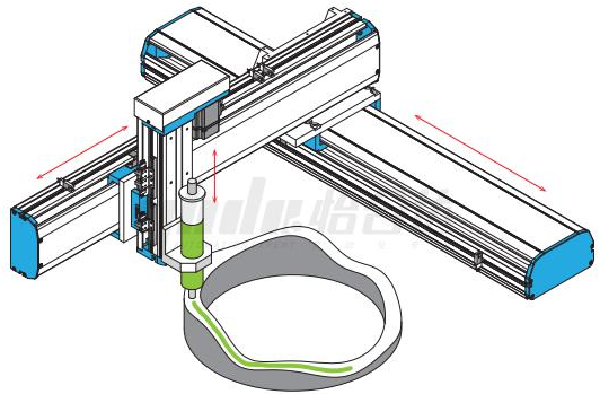

(4) Three-Dimensional Stereoscopic Dispensing

Three-axis linkage to achieve three-dimensional stereoscopic dispensing.

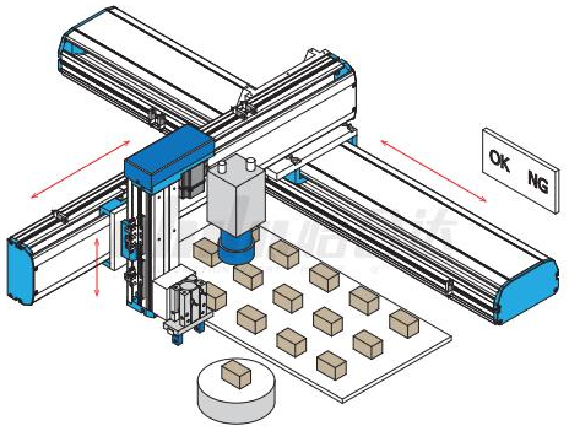

(5)Product Inspection

Detect product parameters such as weight and appearance to determine whether the product is qualified.

(6) Automatic Screw Locking

Screws are transported to a fixed position through a vibrating plate or other devices. The three-week workbench takes the screws and then automatically locks the screws according to the predetermined program.

(7) Visual Inspection

Detect product missing parts and auxiliary material misalignment. Significantly improve the efficiency and accuracy of product inspection. The X-axis and Y-axis drive the camera to perform planar two-dimensional motion, and the Z-axis is equipped with a camera to adjust the focal length. The product qualification is judged through visual inspection.

Model Selection Method

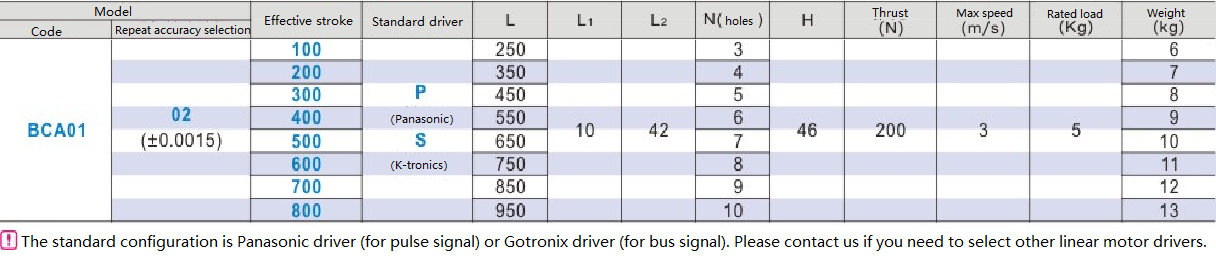

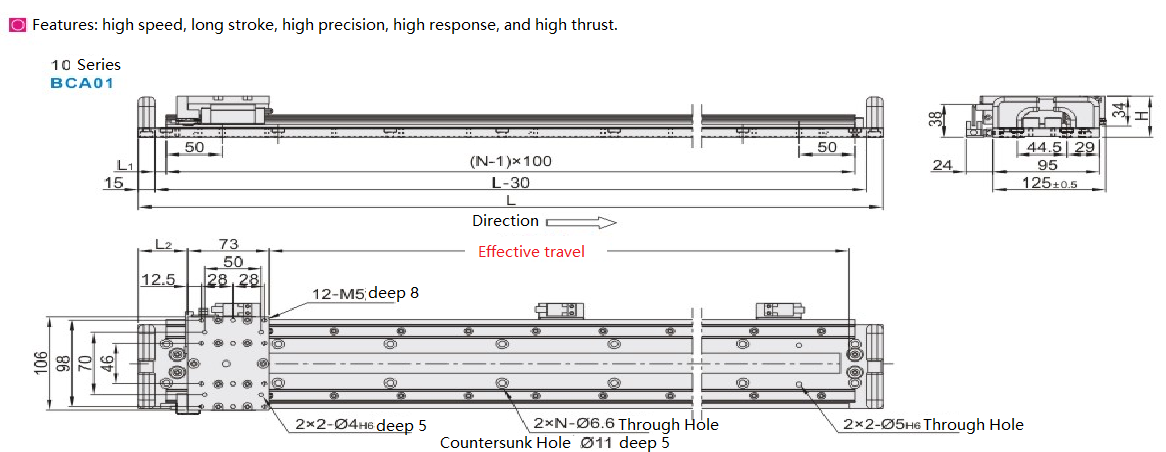

Taking the BCA01 type linear motor as an example: The following is the selection table:

Selection: According to the selection data, first obtain the parameters you care about, such as accuracy and effective stroke. Select according to the environment you use.

Example: The selection requirement this time is to transport parts after installing the fixture, and the transportation distance is 200mm. Then our effective stroke needs to be selected to 300mm, leaving a certain stroke space before and after to prevent impact (do not choose the effective stroke consistent with the required stroke). The load is 1kg, and the speed (V) is to complete the 200mm transportation action within 2S. The positioning accuracy is ±0.05.

According to the conditions, the selected model is: BCA01 - 02 - 300 - S.

* Appropriate performance margin should be reserved during design selection.

Linear Module Maintenance

Regularly clean the dust on the mechanism and try to avoid using it in a humid environment. It is recommended to maintain it at least once a quarter.

(1) Wipe the flat belt clean with a clean cloth and check whether the belt is cracked and whether there are tear openings at the edges.

(2) Wipe the oil stain at the bearing position clean with a clean cloth and add new lubricating oil.

(3) Check the belt that transmits between the motor and the roller to see if it is cracked and whether the belt teeth are normal.

Storage and Installation

Avoid dropping or bumping during handling.

When storing this product, it is recommended to place it flat and properly package it to avoid exposure to high temperature, low temperature, and humid environments.

Do not disassemble or modify this product by yourself to avoid foreign objects entering or product damage, resulting in abnormal function or industrial accidents.

When installing, this product should be locked to prevent loosening due to vibration.

When installing the coupling and motor, appropriate components should be selected, and attention should be paid to aligning the shaft centerline before locking the screws. Do not force the installation.

Operation and Use

During operation, the rated conditions recorded in the catalog, such as the maximum speed and load, must be followed to avoid functional damage or industrial accidents.

Avoid dust, chips, and other foreign objects from entering the ball circulation system, causing damage, shortened life, or abnormal function.

The operating ambient temperature should be below 80°C.

In special environments, such as strong vibration, vacuum chambers, clean rooms, corrosive chemicals, organic solvents or agents, extremely high or low temperatures, wet splashing water, oil droplets, oil mist, high salinity, heavy loads, vertical or cantilever installations, etc., please consult our company's sales first to confirm the applicable conditions of this product. When installed vertically, the load is at risk of falling. It is recommended to install an appropriate brake and confirm the normal function of the brake before use.

Maintain

Before the initial use of maintenance, the lubricating oil should be filled up.

Please pay attention to the type of oil.

Different lubricating oils cannot be mixed. Under normal use conditions, it is recommended to check the operating condition once every 100 km of travel, remove dirt, and supplement lubricating oil. Both the guide rail and the lead screw should be lubricated.