Motorized Stage Conditions and Methods of Use

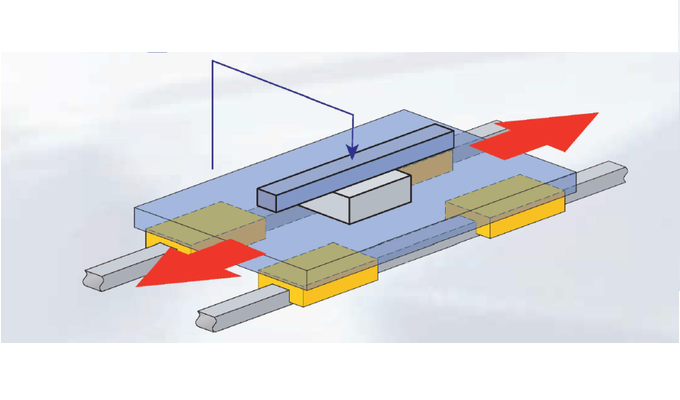

Q: How to use various slide tables (X-axis, horizontal Z-axis, angle, rotation) when installed upside down. How much weaker will the load be compared to the load recorded on the sample (placed horizontally)?

A: The parameters of various products are obtained on the premise that they are placed on a horizontal surface.

Because the load applied to the slide table guide rail changes, the load resistance when installed upside down cannot be clearly defined.

The following is a rough estimate:

◆It can be used when the load center is directly below the top (center) of the slide table.

30% or less of the horizontally placed load

※When the load exceeds the hanging position, the approximate load resistance cannot be estimated and use is not recommended.

・Products other than angle slides

◆Although it can be used when the load center is directly below the upper surface (center) of the slide table, it is difficult to estimate the load-resistant product if the load's force point changes greatly.

Q: What do the CW and CCW directions of the automatic slide mean?

A: The rotation direction of the motor represents the movement direction of the stage.

※The rotation direction of the motor = the rotation direction of the motor shaft seen from the side of motorized stages (opposite to the direction of the motor knob)

◆CW(=ClockWise/clockwise)

The rotation on the motorize stage is opposite to that of the motor.

◆CCW(CounterClockWise/Counterclockwise)

The motorize stage rotates in the same direction as the motor.

Linear slides (XY slides) and angle slides are the same as above.

In the case of a horizontal Z-axis slide table and a rotary slide table, the movement direction of the table top on the slide table is as follows.

<Horizontal Z-axis slide table>

CW direction: upward on the sliding platform

CCW direction: top down on the sliding platform

<Rotating slide>

CW direction: the sliding table rotates clockwise

CCW direction: counterclockwise rotation on the sliding table

Definition of Precision

Q: What's the difference between allowable moment load and moment rigidity?

A: ◆Allowable moment load [Unit: N・m]

Maximum moment load that can be applied to the slide surface.

※Permissible criteria

1. The operational feel is not significantly weakened

2. After uninstallation, the accuracy is still within the sample guaranteed value.

◆Moment rigidity [unit: “/N・cm]

Relative to the surface of the slide table, the displacement angle per 1N·cm centered on the moving surface of the slide table when a moment load is applied in any direction such as up and down swing, left and right swing, or axial rotation.

※Based on the distance from the center of the slide table moving surface (upper surface). ※The moment rigidity listed in the product catalog represents actual measured values.

Q: What is the definition of swinging up and down, shaking left and right, and axial rotation?

A: ◆Swing up and down

Axial rotation of vertical (left and right) intersecting axes relative to the forward direction (front and back)

→tilt up and down

◆Shake left and right

Axial rotation of vertical (up and down) intersecting axes relative to the forward direction (front and back)

→Tilt left and right

◆Axis rotation

Axial rotation relative to forward (front and rear) axis

Q: What is the difference between straightness, up and down swing, and left and right swing?

A:

◆Straightness [unit: μm]

・The maximum offset (distance) in the horizontal or vertical direction relative to the ideal movement axis

◆Swing up and down [unit: "]

・Maximum vertical angle change value

◆Shake left and right [unit: "]

・Maximum horizontal angle change value

Q: What is the difference between the eccentricity and surface runout of a rotary slide?

A:

◆Eccentricity [unit: μm]

・The amount of horizontal displacement of the rotation center axis is regarded as the amount of eccentricity

◆Surface runout [unit: μm]

・The outer edge of the moving surface of the slide table fixed on the reference plane is used as the measurement point, and the maximum displacement difference relative to the reference plane after one rotation is used as the surface runout amount.

Q: What is the difference between parallelism and motion parallelism?

A:

◆Parallelism [Unit: μm]

・Fix the slide table on the reference plane.

・Measure the parallelism of the moving surface relative to the reference plane over the entire surface, and take the maximum height difference as the parallelism.

◆Parallelism of motion [Unit: μm]

・Fix the slide table on the reference plane.

・Measure the displacement between the reference plane of each positioning point and the measuring equipment fixed on the moving plane.

・The maximum difference is used as motion parallelism

Q: What is the difference between one-way positioning accuracy, repeated positioning accuracy and idling?

A:

[One-way positioning accuracy] refers to the deviation between the actual position and the theoretical position when the slide moves a certain distance at any position within the stroke.

[Repeat positioning accuracy] refers to the deviation between the actual position and the theoretical position each time when the slide table continuously reciprocates in one direction at any position within the stroke.

[Idle rotation] refers to the deviation between the actual position and the original position when the slide table is positioned at any position within the stroke and the slide table is positioned reciprocally in the forward and reverse directions at the same point. It is the invalid stroke of the slide.

Motorized Stage Selection

Q: The installation of the slide table is limited and the entire length must be considered. Is there a center stroke on the slide table in the sample drawing?

A: In principle, all slide tables have center stroke

◆Manual slide

The amount of movement is expressed in ±.

For example, in the case of ±10mm, take the position shown in the drawing as the center, move 10mm in the negative direction, and 10mm in the positive direction.

(※Full stroke 20mm)

◆The automatic slide movement is expressed in full stroke. For example, when the movement amount is 100mm, it is centered on the position shown in the drawing and moves 50mm in the + (CW) direction and 50mm in the - (CCW) direction.

【exception】

There are exceptions for manual Z-axis slides・

The movement amount of the specification is not expressed in ±. The movement amount in the positive direction and the negative direction is expressed separately.

Q: What do initial speed (starting speed), acceleration time, driving speed, and maximum speed mean?

A:

・Initial speed (starting speed): the speed when the slide starts to move.

・Acceleration time: The acceleration time from the initial speed to the driving speed

・Driving speed: The speed of uniform driving.

・Maximum speed: The highest value of the drive speed that can be set.

Q: If the acceleration setting is not out of tune, what would it be like?

A: Depending on the workpiece weight, shape, center of gravity position, ball screw lead, etc., there are no clear regulations.

There are many cases where it is adjusted to 100msec~200msec.

Q: Products with a load capacity of 10kg carry a workpiece of 1kg. Will the maximum speed be faster than the sample value?

A: Even if a certain condition is relaxed, the sample guarantee value remains unchanged. Please use within the sample guaranteed value.

Q: What is resolution?

A: Slide movement amount for 1 pulse signal

Q: What do full-stepping, half-stepping, and micro-stepping of resolution mean?

A:

[Full stepping] refers to the feed motion of the slide table at 1/1 standard step angle of the stepper motor.

[Half-stepping] refers to the feed motion at which the step angle of the slide motor is subdivided into 1/2 the standard step angle.

[Micro-stepping] means that the step angle of the slide motor is subdivided into the feed motion at the 1/N standard step angle (N is a positive integer 1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200, 250).

Q: Will the maximum speed be slower after subdividing the resolution?

A: After subdividing the resolution and sending multiple pulses to the driver, the speed remains unchanged. However, the controller has a pulse setting range, so please use it within the range.

How to slow down the movement speed of the slide?

Through the speed parameter setting of the control end, the number of pulses sent by the controller per unit time is reduced.

Repair and Maintenance

Q: How often does it need to be inspected to maintain the accuracy of the automatic slide?

A: There are no specific regulations for maintenance. It varies according to the usage environment (temperature, humidity, etc.), loading method, frequency of use, etc.

Q: How to add grease?

A: The step as following

①Wipe off any old grease that can be seen.

② Use a syringe, etc. to apply it on the guide rail and ball screw.

③Carry out multiple full-stroke movements.

④ Wipe off the spilled grease.

Q: Are there any regulations or recommendations for grease refilling frequency?

A: No matter what kind of grease it is, there is no specific standard for regular refilling. The refilling frequency varies depending on the driving conditions and guide rail type. Customers can check the status of the grease once a month and refill the grease as needed.

Q: It was used within the parameters of the sample specifications (MAX speed, load resistance), but the slide table was out of adjustment. What is the reason?

A:

Out of tune (lost steps) are generally caused by a variety of factors.

·The load is too heavy and exceeds the load capacity of the slide table. The load capacity of the slide should be reduced.

·The speed is too fast and exceeds the rated maximum speed of the slide. The actual operating speed of the slide should be reduced.

·Excessive acceleration. The acceleration and deceleration settings when the slide starts and stops should be confirmed.

·Excessive bending moment load. The load center should be set at the center of the sliding table as much as possible.

·There may be problems with the driver settings.

What' more, you could read more knowledge about manual positiong tables: FAQs Guide on Manual Positioning Table