What is a Manual Positioning Stages

A manual positioning stage is a mechanical device that moves and positions an object on a flat surface. It usually consists of a platform and at least two rails, which are equipped with sliders and adjusting screws to manually adjust the position and direction of the platform. The manual displacement table is commonly used in optics, mechanics, electronics, etc. laboratories for precision positioning, adjustment, and measurement operations.

Manual Positioning Table Structure Characteristics and Advantages

A manual positioning stage is an adjustment device that can manually control the position and direction. It is usually used in fields that require high-precision manual adjustment, such as optical experiments.

To ensure the quality and performance of the manual displacement table, high-quality materials, such as stainless steel and aluminum alloy, are used to improve its rigidity and stability. In addition, after replacing the special grease for the vacuum, the manual displacement table can be used in a vacuum environment, which is suitable for fields such as optical experiments that require high-precision manual adjustment.

The guide rail of the manual displacement table is one of its core components. According to the different needs of customers, different types of guide rails can be selected, including linear ball guide, crossed roller guide, and steel bar ball guide. Crossed roller guide adopts a special roller holding mechanism, making it high precision and rigidity. The effective travel of linear ball bearing guide is relatively high. Steel bar ball guides are much less costly.

There are also many drive mechanisms for manual displacement tables, and different types can be selected according to the needs. The common drive mechanisms for translation or lifting tables are the differential head, threaded sub, grinding screw, gear set, rack and pinion, cam and wedge types, etc. While rotary tables and angular displacement tables usually use a worm gear drive mechanism.

To achieve precision adjustment, the manual displacement table adopts ultra-fine tooth fine-grinding thread sub with a unique locking mechanism, effectively improving stability and sensitivity. In addition, the manual displacement table is equipped with a double locking mechanism. The rear end of the threaded sub has a hexagonal adjustment hole, which can be adjusted with the standard adjustment handwheel or hexagonal wrench to further enlarge the rotation radius and increase the adjustment sensitivity.

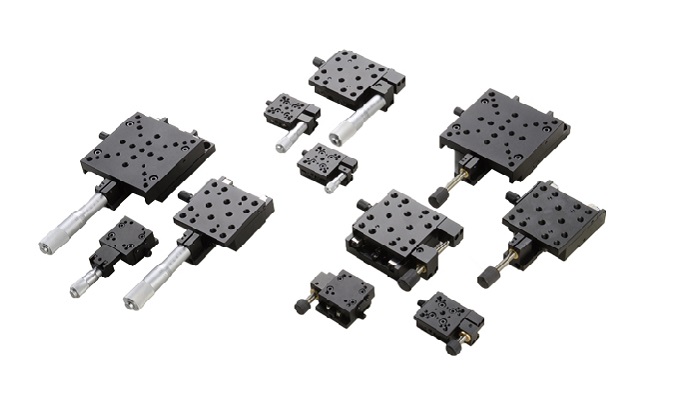

Finally, the manual displacement table can be single-axis or multi-axis, such as X-axis, XY-axis, XZ-axis, etc. In addition, rotary displacement tables and angular displacement tables are also available to meet different usage requirements.

Applications of Manual Positioning Stage

A manual positioning stage is a device commonly used in precision machining, inspection and measurement, optical instruments, semiconductor manufacturing, and other fields, which can be manually controlled to achieve small displacement adjustment. The following is the introduction to the application of manual displacement tables in different fields:

Precision processing field: manual xyz-axis stage is widely used in precision processing, such as precision turning, mirror processing, micro, small hole processing, etc... The manual displacement table can realize tiny adjustments to meet the high-precision machining requirements.

Inspection and Measurement of Manual Positioning Table

Manual positioning stage is also widely used in the inspection and measurement field, such as the measurement of optical components, dimensional measurement of precision parts, etc... The manual displacement table can realize the tiny displacement adjustment, which makes the measurement results more accurate and reliable.

Optical instrument field: manual xyz-axis stage can be applied to the manufacturing and debugging of optical instruments, such as telescopes, microscopes, lasers, etc... The manual displacement table can realize the tiny displacement adjustment to help the optical instruments reach the best performance and accuracy.

Semiconductor manufacturing field: positioning stage is also widely used in semiconductor manufacturing, such as chip packaging, wafer manufacturing, etc.. The manual displacement table can achieve small displacement adjustments to help the semiconductor manufacturing process to achieve higher precision and efficiency.

In short, the manual displacement table has important application value in precision processing, inspection and measurement, optical instrumentation, semiconductor manufacturing, and other fields. It provides strong support for the research and development of these fields.

Applications for Manual Positioning Stage and Their Corresponding Specification Options

CCD camera position adjustment

Selected specifications: EJP01-60, EJQ01-60

Guidance form: dovetail slot type

Adjustment direction: X-axis, Y-axis, Z-axis

Adjustment stroke: ±21mm

Load capacity: 2kg

Camera position adjustment for glass substrate and film inspection equipment

Selected specifications: ELK01-60, E-EIC01-60, ELF01-60

Guidance type: Dovetail groove type, cross roller type, sliding friction type

Adjustment direction: radian, X-axis, θ-axis

Adjustment stroke: ±20°, ±6.5mm, 360° coarse adjustment and ±5° fine adjustment

Load capacity: 3kg

Laser displacement meter positioning

Selected specifications: EJA01-60-QC, EJW01-60

Guidance form: cross roller type

Adjustment direction: X-axis, horizontal z-axis

Adjustment stroke: ±6.5mm, ±5mm

Load capacity: 4kg

For microscope carrier and focus adjustment selected

Specification:HHB31 series

Guide form: linear guide / guide axis adjustment

Direction: X-axis, Y-axis

Adjustment stroke:±13mm

Load capacity:4Kg

The above is the manual displacement table specification options on different occasions and their characteristics. Different load capacities, adjustment directions, and strokes must be considered when selecting to meet the actual demand.

Product Selection Principles and Precautions for Use

The principle of selecting a manual displacement table

Material characteristics should meet the strength requirements and have sufficient load-bearing capacity.

According to the demand to determine the positioning table material, specification size, transmission mode, stroke, load, precision, mounting hole size, transmission direction, and other data, and according to the provided parameter table, select the appropriate displacement table.

Product quality is an important criterion for selecting a displacement table, but also consider the price and seek cost performance.

Notes on the use of manual positioning stage

Installation fixed

Move the platform surface to the limit position to reveal two installation holes, then put the matching bolts in and tighten them to a certain degree. After confirming the coincidence with the installation position, fix the bolts of the 2 mounting holes completely first, and then fix the bolts of the first 2 mounting holes.

Please avoid collision and crushing when assembling and unloading the displacement table and avoid damage.

The allowable range of load direction

Before using the manual positioning stage, please check whether the displacement table can slide smoothly in the appropriate direction of transmission and whether there must be no collision with the workpiece.

All accessories used with the manual displacement table should be able to move smoothly.

Environmental factors

According to DIN/EN norms, the working load of the manual positioning stage will be reduced by the temperature and will return to normal if the temperature returns to normal.

The positioning stage can not be used in an environment higher or lower than the general temperature, the recommended environment: 22±5℃, 20~70%RH (non-condensation), and must not be used in a chemical environment, such as acid, alkali solution, or high-temperature steam environment.

If used in a chemical environment cannot be avoided, please contact the manufacturer first and inform the concentration of acid and alkali, temperature, and various environmental factors for evaluation.

The displacement table needs to be inspected continuously and regularly. Your company should send maintenance personnel or personnel with relevant knowledge to inspect the table regularly and continuously to see if any damage or defects occur.

Other Manual Positioning Stage Installation Methods

Installation method of manual displacement table

Please make sure that there is a (different from the one for installing other size bolts) large hole on the top of the stage for putting in the bolts. Please loosen the locking screw first, and then install the fastening bolt).

2) Next, please push the turning handle (if there is no turning handle, please turn the platform surface directly) to align the mounting hole at 1 with the mounting hole at 1 on the platform body.

3)After aligning the position, put in the bolt and tighten the bolt to a certain degree. When toggling the turning handle, please turn the platform surface slightly to the left and right to confirm whether the bolt is completely into the mounting hole. If it can be turned smoothly, it means that the screw has completely entered the mounting hole.

(4) Repeat the above operation to temporarily fix 3 or 4 mounting holes (varies depending on the type of platform) and then fully fix them in turn.

Swing table installation method:

1)Turn the knob clockwise and move the platform surface to one side. (Please loosen the tightening knob first and then do the operation.) As shown in the figure below, 2 mounting holes are exposed, please put the attached bolts in these 2 places first and tighten them to semi-fixed state. (Please do not tighten them very much. It is only temporary fixation. At this point, make sure that the bolts are fully inserted into the bolt mounting holes, and then proceed with the second operation).

2) Next, turn the knob counterclockwise to move the platform to the other side. On the side opposite to the previous position, two other mounting holes will be exposed. Please put the remaining 2 bolts in these 2 mounting holes and screw them to the semi-fixed state. After confirming the fit with the mounting part, fully fix the bolts of the last two mounting holes first, and then fully fix the bolts of the first two mounting holes.

Note: The above installation is subject to the tightening of the slide without shaking. The fixing screws should be provided by our company (in order to control the length).

Summary

The manual positioning stage is widely used in many fields for precision machining, measurement, and commissioning. Its main advantages include low price, easy operation, and high accuracy. At the same time, it also has some disadvantages, such as manual operation may introduce errors, tedious operation, etc... Therefore, the following recommendations need to be noted when using a manual displacement table:

When choosing a manual positioning stage, the appropriate model should be selected according to the specific application scenario and the required accuracy to ensure that the required accuracy and stability are met.

When using the manual positioning stage, attention needs to be paid to keep the table surface smooth to avoid introducing errors. Also, attention needs to be paid to the strength and angle of manual operation to avoid introducing errors.

Regular maintenance and calibration are required to ensure proper operation and accuracy when operating the manual displacement table.

In conclusion, manual positioning stages have important applications in many fields. Still, attention must be paid to their operation and maintenance to give full play to their advantages.