In the field of industrial automation, single-axis robots are mainly used in work scenarios that require linear motion. So we need to have some basic understanding of the advantages and disadvantages of some common and practical single-axis robot structures.

Rodless Cylinder With a Shaft

The structure of a cylinder with a shaft should be one of the most basic types of structures in single-axis robots, and rodless cylinders are generally used. The advantages and disadvantages of such basic structures are clear.

1) Advantages

① The single-axis robot structure of rodless cylinder + axis uses fewer types of parts and has simple installation steps, which can be quickly installed and put into use.

②The overall use cost of the structure is low, and it can achieve effective control during use, and it is also very convenient to use.

The length of the rodless cylinder used can reach up to 3m, and the accuracy can be guaranteed to be around 0.01mm.

2) Disadvantages

① Due to the limitations of the rodless cylinder product itself, this structure can only achieve linear motion between two points, and it cannot stop and start during the motion.

② The reciprocating motion of the rodless cylinder is a short-stroke motion, so this single-axis robot structure is generally only suitable for strokes within 300mm. This structure is not suitable for scenarios exceeding this stroke.

③ Since the material hardness and load capacity of the single shaft itself are insufficient, it cannot bear excessive loads during horizontal transmission.

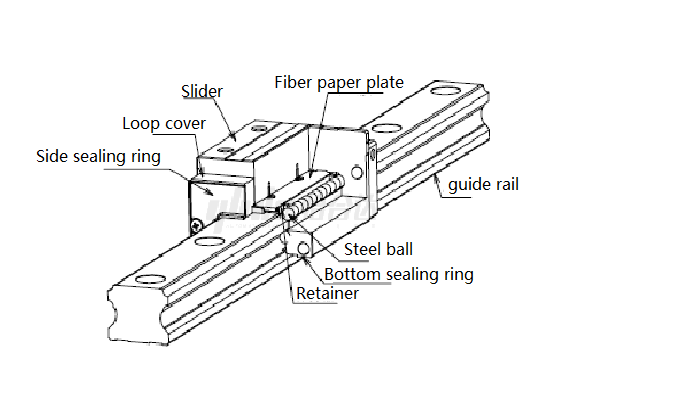

Cylinder With Guide Rail

The difference between a cylinder and a guide rail structure is that the guide rail can bear a much larger load than a single axis. However, the same disadvantage is that the use of a cylinder can only achieve linear reciprocating motion between two points, and it cannot be stopped at any time during the motion.

Motor with Rack and Slide Rail

The addition of the rack and pinion allows this single-axis robot structure to break through the common stroke limitations and can achieve long-distance transmission when used. Features such as the excellent load-bearing capacity of the slide rail and motor control drive also give this structure the corresponding load and the ability to stop and start. The disadvantage is that the addition of gear racks makes the overall structure more difficult to process, and the cost is higher than the previously mentioned structures.

Belt Matching Shaft Matching Motor

This structure uses a motor instead of a cylinder to achieve linear motion. During the movement, it can start and stop at any position driven by the motor and supports transmission performance at multiple positions. However, in actual use, due to factors such as the easy wear of the belt, the overall accuracy cannot be guaranteed, and the problem of a single bearing with a small heavy load still exists.

Motor with Screw

The screw drive structure has the best overall performance and can still ensure high precision and high quality even when working for a long time. Compared with the excellent working performance of this structure, the higher cost and some limitations of the stroke will not affect the screw drive structure's popularity among engineers.

Yiheda single-axis robot: https://www.china-me.com/product/function-module/single-axis-robot