Ⅰ. What is a KK Single Axis Robot?

KK Single Axis Robot is a high-precision transmission mechanism designed through modular integration of ball screws and linear guides. The design incorporates a high-precision ball screw as the driving mechanism and a U-shaped rail groove for guidance, enabling the transformation of rotary motion from the screw into linear motion. The modular design facilitates the integration of these components, resulting in a single-axis robot capable of achieving precise linear movement.

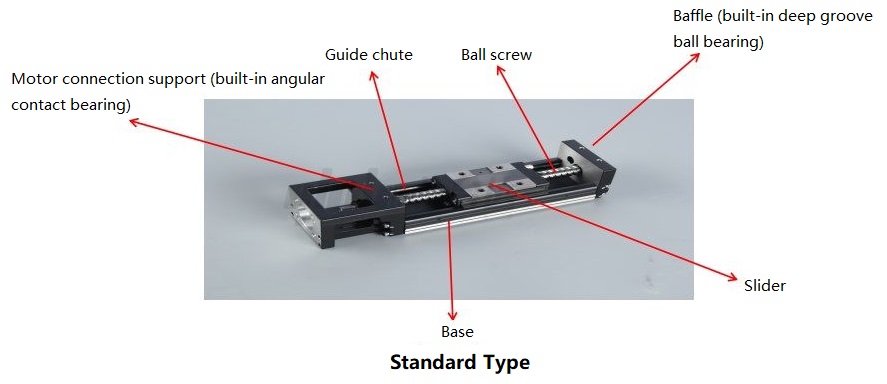

Ⅱ. Product Composition

The KK single axis robot is composed of multiple key components that work together to ensure the efficient operation of the robot. As can be seen from the illustration, products include but are not limited to ball screws, linear guides, motors, etc.

Ⅲ. Usage Occasions

1) Automated feeder and manipulator: KK single-axis robot can be used in automatic feeding mechanical systems to achieve efficient material transportation and flexible operation of the robotic arm.

2) Automatic application of accessories: Suitable for automatic application of accessories to improve accuracy and efficiency.

3) Laser marking: In the field of laser marking, precise marking of workpieces is achieved through precise linear motion.

4) Laser welding: A KK single-axis robot can be used for laser welding tasks to ensure high precision and stability of the welding process.

5) Detect focus equipment, etc.: Provide reliable linear motion support in equipment that requires precise focus.

Ⅳ. Product Features

(1) Easy installation, easy disassembly, and maintenance: The modular design makes installation and disassembly easy, and maintenance is also more convenient.

(2)Small size and lightweight: The small size and lightweight design make the KK single-axis robot easier to integrate into various working environments.

(3)High precision and high rigidity: The use of high-precision ball screws and linear guides ensures high precision of movement and high rigidity of the system.

(4)Conducive to design and matching: The flexible modular design makes the KK single-axis robot easy to design and match with other equipment and systems.

(5) A variety of stroke specifications are available, and the motor can be installed in a folding direction: a variety of specifications are provided to meet the needs of different working scenarios, and the motor installation is more flexible.

Ⅴ. Product Selection Principles

The following factors should be considered and confirmed when purchasing a KK single-axis robot:

(1) Confirmation of stroke: Determine the working range that the robot needs to cover to select appropriate stroke specifications.

(2) Working condition considerations: Depending on whether there is dust and foreign matter in the on-site environment, select appropriate protective measures, such as protective covers or organ covers.

(3) Motor specifications: Select the corresponding connecting flange and motor connection support according to the motor specifications to ensure stable operation of the system.

(4) Load verification: Check the module load and torque according to the load size and installation method, and select the module that meets the requirements.

(5) Speed requirements: According to the speed requirements, select the screw lead and motor specifications to meet the work efficiency requirements.

(6) Limit switch: Considering safety factors, ensure that the slider positioning, starting origin, and module walking safety limit are provided.

(7) Usage occasions: Choose precision-grade or standard-grade modules according to usage occasions to meet different application needs.

Ⅵ. Installation and Disassembly

The countersunk hole of the module base and the mounting platform are connected and fixed with screws.

Installation method: horizontal installation, vertical installation, wall installation.

Ⅶ. Maintenance

(1) Avoid falling or colliding when transporting, and avoid using it in high-temperature, low-temperature, or humid environments.

(2) Do not disassemble or modify this product by yourself to avoid malfunction and damage to the module.

(3) During installation, screws should be used to tighten the module and the installation platform to prevent it from falling off due to vibration.

(4) When operating, strictly follow the motor speed, load, etc. specified in the catalog and instructions to avoid functional damage.

(5) Dust, impurities, and foreign matter should be prevented from entering the inside of the ball screw to avoid damage, shortened life and abnormal function.

(6) When installing vertically, a motor with brakes should be used to prevent the load from falling and damaging the module after a power outage.

(7) The lubricating oil should be filled up before first use. Different lubricating oils cannot be mixed.

(8) Under normal use, it is recommended to check the operating status once every 100km and clean up dust and impurities promptly.

(9) Maintenance steps are as shown in the figure:

Ⅷ. Frequently Asked Questions and Analysis

(1) The screw rod is stuck and makes abnormal noise: There may be foreign matter in the screw rod, which needs to be checked and cleaned in time.

(2) The screw is not smooth: It may be due to lack of oil. Just add oil to the screw, guide slide, and bearings.

(3) If the module is rusty: Use anti-rust oil to remove rust in time to maintain the smoothness of the module surface.

(4) Module parts are damaged: Parts need to be repaired or replaced in time to maintain stable operation of the system.

Ⅸ. Example Cases

Picking and feeding mechanism

Equipment name: Dual-axis rotary picking and feeding mechanism.

Design purpose: Automate and accurately pick and feed materials, save manpower, and improve work efficiency. Parts application instructions: Control the movement of materials in two directions through the movement of the X and Y axes. The speed can be changed by adjusting the motor speed. A rotating cylinder is connected to the socket to ultimately realize the movement and rotation of the material in two directions, improving the degree of automation.

For more product knowledge, please visit the Yiheda Product Knowledge