Flexible drag chain cables are a special category within the range of electrical wires and cables, generally referring to cables that can move back and forth with the drag chain and have strong wear resistance and high flexibility. Flexible drag chain cables are commonly seen in scenarios requiring reciprocating motion in industrial automation and automated production lines.

Structural Composition

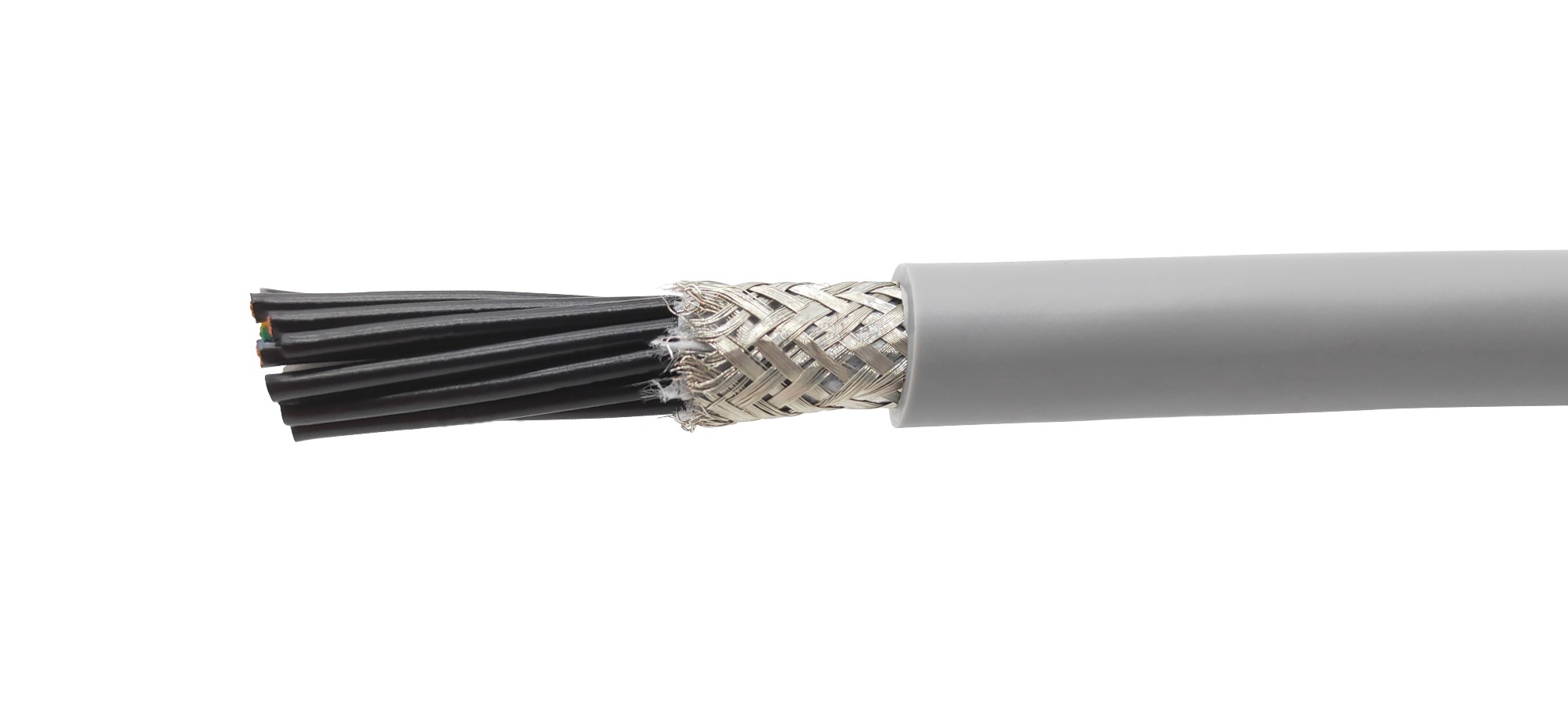

The structure of flexible drag chain cables includes:

- Conductor: Multi-strand fine copper wire conductor, conforming to IEC 60228 Class 6 conductors.

- Insulation: High mechanical performance insulation TPEE drag chain cable special insulating material.

- Color: Black with numerical identification, twisted pairs are red and blue.

- Inner Shielding: Aluminum foil Mylar wrapped around woven tinned copper mesh.

- Braiding: Bare copper wire or tinned copper wire braided servo cable high-density shielding (optional).

- Sheath: Mixed 80-degree heat-resistant flame-retardant PUR sheath, passed VW-1 flame test; customizable.

Advantages and Features of Flexible Drag Chain Cables

In the fields of industrial automation and robotic technology, flexible drag chain cables (Flexible Cable Trough) are a very important transmission medium. Below are the advantages and features of flexible drag chain cables to help you better understand and choose the right cable products.

1. Protect Cables from Damage

One of the main features of flexible drag chain cables is to protect cables from damage. In industrial environments, cables may be subject to various mechanical stresses, such as bending, twisting, stretching, and compression. Flexible drag chain cables use special structural designs to effectively resist these stresses, protecting the cables from damage and thus extending their service life.

2. Good Bending Performance

Flexible drag chain cables have good bending performance and can bend smoothly at various angles and radii. This makes flexible drag chain cables highly flexible in robots and automated equipment, easily adapting to various complex working environments.

3. Wear Resistance and Anti-Aging

Flexible drag chain cables produced by Yiheda use high-quality materials and advanced production processes, which have good wear resistance and anti-aging properties. This means that the performance and life of flexible drag chain cables can be guaranteed during long-term use.

4. Good Heat Dissipation Performance

Flexible drag chain cables use special materials and structural designs, which have good heat dissipation performance. This allows flexible drag chain cables to work normally in high-temperature environments, ensuring the stability and reliability of equipment.

5. Lightweight and Portable

Flexible drag chain cables are lightweight, easy to carry, and install. This makes flexible drag chain cables more convenient in movement and installation, saving time and cost.

6. Various Specifications and Models

Flexible drag chain cables produced by Yiheda come in various specifications and models to meet the needs of different customers. Customers can choose the right flexible drag chain cable products according to their application scenarios and needs.

Design Features and Technical Parameters of Flexible Drag Chain Cables

Our flexible drag chain cables focus on the following key features and technical parameters in the design and manufacturing process:

- Conductor Material: Multi-strand fine copper wire conductor, conforming to high standards of electrical conductivity requirements, ensuring stable current transmission and electrical performance.

- Insulation Material: High mechanical performance TPEE material is used as insulation, with excellent mechanical strength and wear resistance, suitable for frequent bending motion.

- Core Wire Structure: The optimized pitch twisted cable structure is designed to consider the durability under high-frequency bending, using layered or grouped twisting and polyester fiber filling to enhance the durability and stability of the cable.

- Shielding Structure: High-density tinned copper mesh woven shielding, with a density of 80% or more, effectively suppresses external electromagnetic interference and ensures the stability and reliability of data transmission.

- Outer Sheath Material: High mechanical performance PUR mixture is used as the sheath material, with good wear resistance and tensile strength, suitable for long-term use in harsh industrial environments.

Installation Precautions for Flexible Drag Chain Cables

1) The installation of flexible drag chain cables should not be done by directly unrolling the cable reel or cable spool from one end. The correct method is to first evenly unfold the cable before proceeding to the next installation operation.

2) Regarding the minimum installation radius of flexible drag chain cables, the standard is that the minimum installation radius should not be less than six times the diameter of the flexible drag chain cable.

3) The arrangement of flexible drag chain cables also has established rules. There should be a certain distance between cables. Under permissible installation conditions, they should be arranged separately as much as possible. Generally, the distance between flexible cables in the cable drag chain should be more than 10% of the cable diameter.

4) Throughout the entire installation and use process, both ends of the flexible drag chain cable need to be fixed at the moving end of the cable drag chain. The moving point of the flexible drag chain cable should be within 10% of the cable diameter from both ends of the drag chain.

5) The tensile performance of flexible drag chain cables also has its own limits. During installation, it is even more important to pay attention to the stretching of the drag chain cable and the drag chain. Overstretching should be avoided as much as possible, otherwise, both the flexible drag chain cable and the cable drag chain may need to be replaced at the same time.

6) After the main installation operations of the flexible drag chain cable are completed, it is necessary to confirm again that the flexible drag chain cable can move freely within its bending radius. The reason for this is that the motion between multiple flexible drag chain cables and guiding devices is relative motion. After a period of work, we should regularly check whether the position of the internal flexible drag chain cable has shifted.

Applications of Flexible Drag Chain Cables

Flexible drag chain cables themselves have good bending performance and also have many advantages such as mobile flexibility and wear resistance. Therefore, flexible drag chain cables are often used on automated production lines, robotic arms, and other equipment that require repetitive reciprocating motion. In the use process, flexible drag chain cables also have strong adaptability to the external environment and can overcome the influence of most harsh environmental factors.

Our flexible drag chain cables, with their unique technical advantages and performance characteristics, are widely used in the following fields: industrial automation, where they are used in the drag chains of modern mechanical standard components for logistics systems, control systems, and mechanical automation systems to ensure stable operation and efficient production.

In CNC machine tools and manufacturing, they are applied to CNC machine tools, wood and stone machinery, glass and window machinery, injection molding machines, and other industrial equipment, supporting complex motion control and high-precision processing. In heavy machinery and lifting and transportation equipment, they are suitable for construction machinery, heavy machinery factories, automotive manufacturing, and lifting and transportation equipment, capable of withstanding large mechanical motion and high-frequency bending operations.

Flexible drag chain cables, with their well-designed and technologically advanced features, provide an important solution for energy transmission in modern industrial automation and production. Users in need are welcome to consult Yiheda for suitable cable products!