In mechanical design and manufacturing, the way shaft parts are fixed is a crucial link. The fixation method not only affects the transmission efficiency and mechanical performance, but also affects the stability and safety of the entire mechanical system. Common fixing methods include flat keys, wedge keys, tangential keys, splines, feather keys, semicircular keys, cylindrical pins, tapered pins and interference fits, etc. Each of these methods has its own characteristics and is suitable for different working environments and design needs.

Flat Key

A flat key is a key that relies on two sides as working surfaces, and relies on the extrusion of the key and keyway sides to transmit torque. Flat keys are divided into three types: ordinary flat keys, thin flat keys, and guided flat keys. Ordinary flat keys have good centering, high positioning accuracy, and are easy to fold and assemble, but cannot achieve axial fixation of parts on the shaft. They are used for high-speed or shafts that bear impact or variable loads; thin flat keys are used for thin-walled structures and transmission Where the torque is small; the guide-type flat key uses screws to fix the key on the shaft, and is used in situations where the parts on the shaft move little along the shaft.

Features:

Simple to manufacture, easy to assemble and disassemble, good alignment. It is used in fixed connections with higher precision, high speed and under impact or variable load. It can also be used in guide connections with general requirements. This form is commonly used for the connection of gears, worm gears, pulleys and shafts.

Wedge Bond

Both the upper and lower sides of the wedge key are working surfaces. The upper surface of the key has a slope of 1:100, and the bottom surface of the hub keyway has a slope of 1:100. When the wedge key is driven into the shaft and hub, a large preload force is generated on the surface. During operation, the torque is mainly transmitted by friction and can withstand axial force in one direction.

Features:

It can transmit torque and withstand unidirectional axial force. Due to the eccentricity or deflection of the parts on the shaft after assembly, it is not suitable for strict alignment, impact loads and high-speed transmission connections.

Tangential Key

Features:

Composed of two wedge keys with a slope of 1:100. Its upper and lower surfaces (narrow surfaces) are working surfaces, one of which is in the plane passing through the axis line. The pressure on the working surface acts along the tangential direction of the shaft and can transmit a large torque. A tangential key can only transmit torque in one direction. When transmitting bidirectional torque, two keys at an angle of 120° to 130° to each other must be used.

Application:

Used in situations where the load is very large and the alignment requirements are not strict. Since the keyway greatly weakens the shaft, it is often used on shafts with a diameter greater than 100mm. Such as the connection between large pulleys and flywheels, the drums and gears of large mining winches, etc., and the shaft.

Spline

Spline connections consist of internal splines and external splines. Both internal and external splines are multi-tooth parts. The splines on the inner cylindrical surface are internal splines, and the splines on the outer cylindrical surface are external splines.

Features:

There are rectangular, involute and triangular splines. It has high load-bearing capacity, good centering and guiding properties, but is difficult to manufacture and has high cost. It is suitable for sliding connections or fixed connections with large loads and high centering accuracy requirements. The triangular teeth are small and suitable for connection of small shaft diameters, light loads or thin-walled sleeves.

Slide Key

Features:

The key is fixed on the hub, and the key moves axially along the keyway on the shaft with the hub. Often used in situations where the axial movement distance is large.

Half Round Key

Half round key is a type of key. Its upper surface is a flat surface, its lower surface is a semi-circular arc surface, and the two sides are parallel. It is commonly known as a crescent key.

Features:

Working surface: The working surface of the semi-circular key has two sides, which transmit torque on the sides. Has the same good centering properties as a flat key.

Adapt to tilt: The key can swing in the shaft groove around the center of arc curvature of the bottom surface of the groove, so it can automatically adapt to the tilt of the bottom surface of the hub keyway.

Advantages: Easy to process and easy to install.

Disadvantages: The keyway on the shaft is deep, which weakens the strength of the shaft. It is generally only used in parts with smaller stress.

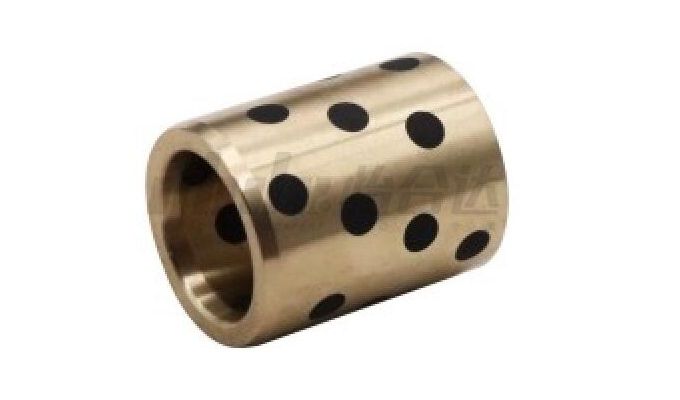

Cylindrical pin

Cylindrical pins are positioning pins used to fix the relative position between parts. It is an important auxiliary part during combined processing and assembly.

Features:

It is suitable for occasions where the hub width is small (such as l/d<0.6) and it is difficult to ensure reliable fixation of the hub and shaft with key connection. This kind of connection generally uses interference fit, and several cylindrical pins can be used at the same time. In order to avoid deflection of the drill bit when drilling, it is required that the hardness difference between the shaft and the hub should not be too large.

Taper pin

Features:

It is used for fixing parts that are not important and do not bear much force but need to be fixed axially, or used as safety devices. Since drilling holes in the shaft will greatly weaken the strength, it is not suitable for heavy-loaded shafts. Open-tailed tapered pins can be used when there is impact or vibration.

Interference fit

Features:

The structure is simple, has good neutrality, and has high load-bearing capacity. It can play both circumferential and axial fixing functions, but it is not suitable for frequent disassembly. For fits with moderate interference, they are often used together with flat key connections to withstand larger alternating, vibration and impact loads.

When selecting the fixing method of shaft parts, designers and engineers need to comprehensively consider the specific requirements of the mechanical system, working environment, load conditions, manufacturing costs and other factors, and reasonably select the most appropriate fixing method to ensure the stability of the mechanical system. and efficiency. The correct fixation method can not only improve mechanical performance, but also extend the service life of the equipment and reduce maintenance costs, thereby achieving the best economic benefits.