Introduction

It is vital to understand the application of various machinery and equipment couplings and select the right coupling. This article introduces the features and applications of various couplings to help you better understand and select the right coupling for your equipment.

Product Conveyor Belts

Product conveyor belts are indispensable devices in modern industry, and their operational efficiency and stability are essential for productivity improvement. The spindle is a critical component of the product conveyor, and its high torque and speed are essential to ensure the stability and efficiency of the conveyor.

The following are the key points to consider when selecting a spindle:

High-speed transmission capacity: In the process of high-speed operation, the spindle needs to withstand high-speed transmission capacity, so the selection needs to consider the bearing capacity and wear resistance of the spindle to ensure the stability and long service life of the conveyor belt.

High torque transmission capacity: In the operation process, the conveyor belt needs to withstand large loads and torques, so the selection needs to consider the high torque transmission capacity of the spindle to ensure that the conveyor belt can run stably and be used for a long time.

For these two points, the cross-ring coupling is an ideal choice. This coupling allows for large eccentricities and eccentric angles through the slippage of the sleeve and spacer, reduces the burden on the shaft, and is electrically insulated to protect the electrical system of the conveyor belt and improve safety.

In addition, due to the smaller variation of shaft load caused by the error adjustment, the conveyor belt with cross-ring coupling can operate more stably, reducing the failure rate and improving productivity.

In conclusion, by choosing a spindle with high speed and high torque transmission capability and equipped with a cross-ring coupling, the stability and efficiency of the conveyor belt can be significantly improved, which in turn increases industrial productivity and profits.

Surface mounter

Surface mounter is a kind of high-precision equipment widely used in the electronic manufacturing industry, and its accuracy and stability have a vital impact on product quality and efficiency. In the design of the surface mounter, coupling is a vital component. Its high precision and zero rotary clearance play an important role in ensuring the stability and reliability of the equipment.

The following are the key points to consider when selecting the coupling:

High precision: The coupling needs to have a high-precision transmission capability to ensure the equipment can maintain stability and precision when running at high speed. The manufacturing process and materials of the coupling need to be considered when selecting the type to ensure its accuracy and wear resistance.

Zero slewing clearance: During operation, the coupling needs to have the feature of zero slewing clearance to ensure that the equipment can run stably. The design and structure of the coupling need to be considered when selecting the type to ensure that it has the characteristics of zero slewing clearance.

The all-stainless steel threaded coupling is an excellent choice for these two points. This coupling features high precision and zero backlashes, improving the equipment's stability and accuracy.

In addition, the coupling has the following advantages:

Good corrosion resistance: The stainless steel material has excellent corrosion resistance, which can effectively protect the equipment from corrosion and oxidation, thus extending the service life of the equipment.

Easy to install: The threaded wire coupling has the feature of easy installation, and only a simple installation operation is required to complete the coupling installation, saving the equipment's maintenance time and cost.

In short, choosing all stainless steel threaded line coupling with high precision and zero rotary clearance can improve the surface mounter's stability and precision, extend the equipment's service life, reduce the equipment maintenance time and cost, and improve productivity and profit.

Genetic Testing Equipment

Genetic testing devices are important equipment in modern medicine, and vibration-damping couplings are an integral part. The followings are the selection points and products used for vibration-damping couplings:

Selection points:

High vibration absorption capability, realizing silent performance.

A high gain of the servo motor can be realized, shortening the adjustment time and improving efficiency.

Adopted products:

Vibration-damping coupling

By using high vibration-absorbing rubber and optimizing the rigidity of the design, the vibration-absorbing coupling can greatly reduce vibration and noise and achieve efficient transmission capability. The following are specific advantages:

Advantages:

Achieves high vibration absorption, reducing vibration and noise transmitted to the equipment

Optimized design for increased rigidity, reduced set-up time, and increased efficiency.

Completely integrated construction for increased stability and reliability

High-quality materials for vibration-damping couplings, such as all stainless steel couplings, ensure high durability and long life. Vibration-damping couplings are also an important part of genetic testing devices in modern medicine, enabling medical technology's continuous improvement and development through their efficient transmission capabilities.

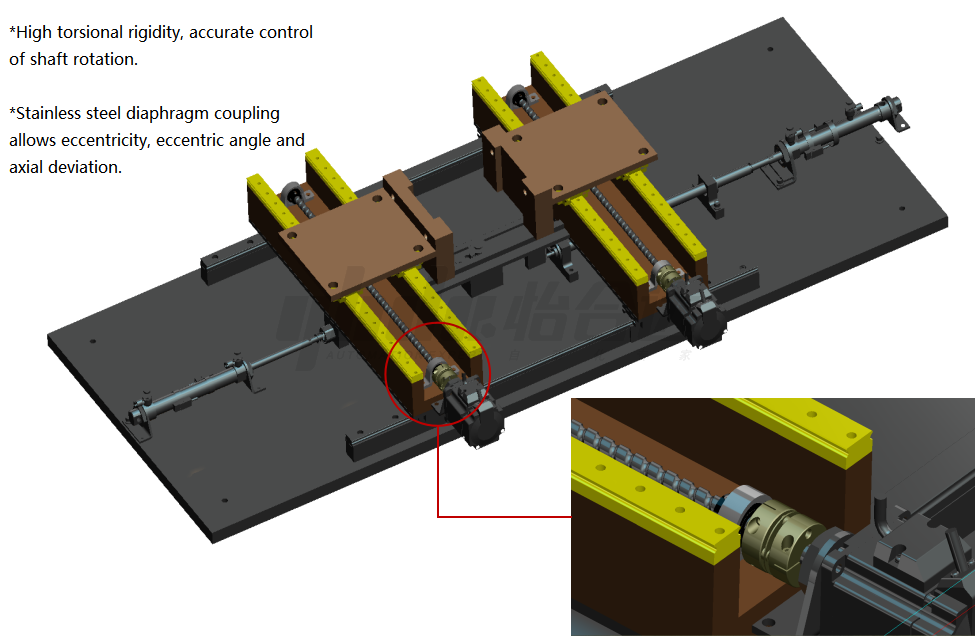

Battery Assembly Unit

The battery assembly unit is a machine that requires high precision, high torque, and high speed. It is critical to select the right coupling. The following is more information on the selection of this equipment and the products used:

Selection points:

High Torque: High torque needs to be transmitted to ensure proper assembly of the cell components.

High Speed: High speed is required to increase assembly efficiency and production speed.

Products used:

Single diaphragm coupling: This coupling can transmit high torque and rotational speed with high torque rigidity and the ability to accurately control shaft rotation.

Stainless steel diaphragm coupling: The design of this coupling allows for eccentricity, eccentric angle, and axial misalignment. At the same time, the stainless steel material ensures that the coupling is highly corrosion-resistant, helping maintain the equipment's long-term stability.

When using a single diaphragm coupling as a drive component in a cell assembly unit, the following advantages are also available:

High precision: Higher precision and stability can be achieved due to the high rigidity of the single diaphragm coupling, which enables accurate control of shaft rotation.

Reliability: The single diaphragm coupling is designed to have high reliability and durability to meet the requirements of long-time and high-intensity work requirements.

Therefore, using single diaphragm coupling as the transmission component of the battery component assembly device can improve the efficiency and stability of the equipment and meet the requirements of high precision, high torque, and high speed.

Lathe

Simple structure, and high transmission torque, can effectively compensate for axial and radial deviation.

Key points of selection: Using chain as coupling point, easy to disassemble and install, high rotating torque

Adopted products: Chain coupling

As a traditional metal processing equipment, the lathe has always been one of the essential pieces of equipment for various manufacturers. Modern lathes have been developed in various high-end and precision forms. Among them, chain coupling is one of the commonly used couplings on lathes, which has the following advantages:

Special chain design can effectively compensate for axial, radial, and angular deviations, thus improving machining accuracy.

The simple structure of chain coupling, very easy disassembly and installation, and low maintenance cost.

The chain made of special material can transmit large torque to meet the demand of high-speed lathe rotation.

Chain coupling has been widely used in various lathes, such as CNC lathes, general lathes, gear hobbing machines, etc.

The lathe with chain coupling has the characteristics of high precision, high stability, and high efficiency in processing, which can meet the processing requirements of various metal parts and provide high-quality processing services for various industries.

Cartoning machine

A case packer is a machine and equipment used to pack items. The case packer must convey high torque with high precision concentricity and straight progress to ensure its efficiency and accuracy. Here we introduce a coupling whose material selection point is to convey high torque and high precision concentricity: long-span coupling.

The long-span coupling is made of highly rigid aluminum alloy material to achieve a low moment of inertia and has the following features:

For transmitting high torque: Long-span couplings are designed with high torque transmission in mind and can withstand high torque while maintaining transmission accuracy and stability.

High-precision concentricity and straightness: The case packer needs to pack the items with high precision, it needs to have high precision. Long-span couplings can meet these requirements and maintain the accuracy and stability of the transmission.

Significant vibration absorption effect: the carton will produce vibration when working. The long-span coupling can significantly absorb vibration, reduce damage to the machine and equipment, and improve efficiency and stability.

Zero rotary clearance: The long-span coupling adopts a special design and manufacturing process, which can realize zero rotary clearance and keep the accuracy and stability of the transmission.

In a word, using long-span coupling as the coupling of a cartooning machine can effectively transmit high torque with high precision concentricity and straight progress while absorbing vibration significantly and maintaining the accuracy and stability of the transmission.

Turntable Solder Dispenser

A turntable Solder Dispenser is a kind of equipment used for printed circuit boards, which needs to have the characteristics of high speed and high precision transmission. To meet these requirements, the selection of Plummer couplings can effectively improve the performance and stability of the equipment.

The following points need to be considered when selecting a plum coupling:

High speed: The spindle of a turntable tin-dispensing machine needs to have high-speed characteristics, so choosing a coupling that can withstand high speed is necessary.

High-precision transmission: The tin-dispensing machine needs high-precision transmission to ensure the quality and stability of printed circuit boards. Therefore, the coupling also needs to have the characteristics of high precision.

The advantages of the more plum-type coupling are:

Zero backlash torque transmission: When tightening, zero backlash torque transmission can be achieved in a low torque condition, thus ensuring the high precision performance of the tin-dispensing machine.

Elasticity effect: Plummer-type coupling has an excellent elasticity effect, which can absorb vibration, eccentricity, and eccentric angle and improve the stability and life of the equipment.

Therefore, using plumber couplings can improve the characteristics of the turntable tin-dispensing machine, such as high torque and high precision of the spindle, ensuring the performance and stability of the equipment.

CT Scanning

CT scanning technology has important applications in the medical industry, and couplings are essential. The following is an introduction to the selection points and products used to select CT scanning couplings.

Selection points:

Corrosion resistance: The environment involved in CT scanning may corrode the coupling, so choosing a stainless steel coupling with high corrosion resistance is necessary.

Zero slew clearance: The zero slew clearance of the coupling directly affects the accuracy of the CT scan, so it is necessary to choose a coupling with a small zero slew clearance.

Adopted products:

Parallel line coupling: This coupling is made of all stainless steel, which has the characteristic of extremely high corrosion resistance. The metal spring design, which is slotted in the cylindrical material and constructed completely in one piece, can effectively reduce the slewing clearance and improve the accuracy of CT scanning.

In short, using couplings with high corrosion resistance and small zero slewing clearance can ensure the accuracy and stability of CT scans, thus improving the accuracy of medical diagnosis.

Medical equipment

Medical equipment requires high torsional, high precision, and ultra-precision control, and double diaphragm couplings are an ideal product choice.

Selection points:

High torsion: Medical equipment needs to withstand high torque to ensure the reliability and stability of the equipment.

High Precision: Medical equipment needs to be controlled with high precision to ensure accurate diagnosis and treatment.

Zero-torsional clearance: Precision and reliability are critical in medical equipment, so couplings with zero-torsional clearance are required.

Benefits of using double diaphragm couplings:

High torsional rigidity: The double diaphragm coupling can accurately control the shaft rotation, ensuring the stability and reliability of the equipment.

High precision: Stainless steel diaphragm couplings can compensate for radial, angular, and axial misalignment for high-precision control.

Identical clockwise and counterclockwise sew-ability: Double diaphragm couplings can achieve precise rotational control in any direction.

Good fault tolerance: In a double diaphragm coupling, the two diaphragms can move independently, thus absorbing deviations and vibrations in different directions, thus improving the fault tolerance and stability of the equipment.

In a word, double diaphragm coupling is a kind of high-performance and high-reliability coupling in medical equipment, with the advantages of high torsion, high precision, zero rotary clearance, and good fault tolerance.

Conclusion

Through this article, we hope we have listed some examples of shaft coupling use, and if you have any customized needs or want to know more about shaft coupling applications, please feel free to contact us. We wish we could help you.