1. Characteristics of Plum Couplings

The plum coupling has a simple structure, does not require lubrication, is easy to maintain and inspect, and is maintenance-free, allowing for continuous long-term operation. The high-strength polyurethane elastic components are wear-resistant and oil-resistant, have a large load-bearing capacity, long service life, and are safe and reliable. It works stably and reliably, with good vibration reduction, cushioning, and electrical insulation properties. It has significant axial, radial, and angular compensation capabilities. The structure is simple, with a small radial size, lightweight, and low rotational inertia, making it suitable for medium and high-speed applications.

2. Functional Characteristics

Axially inserted assembly

High torque transmission

Adjustment of damping performance through the selection of elastomers with different hardnesses.

3. Technical Parameters

|

Specification Outside Diameter |

Rated torque N.m (Shore hardness) |

|||

|

98A |

85A |

92A |

64D |

|

|

14 |

2 |

0.7 |

1.2 |

2.4 |

|

20 |

5 |

1.8 |

3 |

6 |

|

25 |

9 |

3 |

5 |

12 |

|

30 |

12.5 |

4 |

7.5 |

16 |

|

35 |

15 |

5 |

9 |

18.5 |

|

40 |

17 |

5.5 |

10 |

21 |

|

55 |

60 |

/ |

35 |

75 |

|

65 |

160 |

/ |

95 |

200 |

|

80 |

325 |

1 |

190 |

405 |

|

95 |

450 |

/ |

265 |

560 |

|

105 |

525 |

1 |

310 |

655 |

|

120 |

685 |

1 |

410 |

825 |

|

Plummer pad hardness |

Color |

Material |

Allowable working temperature ℃ |

|

|

Continuous |

Instantaneous |

|||

|

98A |

Red |

Urethane |

-50~+80 |

-60~+100 |

|

85A |

Blue |

-40~+90 |

-50~+110 |

|

|

92A |

Yellow |

-30~+90 |

-40~+120 |

|

|

64D |

Green |

-20~+100 |

-30~+120 |

|

4. Temperature Coefficient Kt

|

≤30℃ |

≤40℃ |

≤50℃ |

≤60℃ |

≤70℃ |

≤80℃ |

≤90℃ |

|

1 |

1.2 |

1.3 |

1.4 |

1.55 |

1.8 |

2.2 |

Calculation formula for plum blossom pad selection:

——Rated torque of equipment * temperature coefficient Kt ≤ Rated torque of plum blossom pad

5. Installation of Plum Coupling

Installation steps:

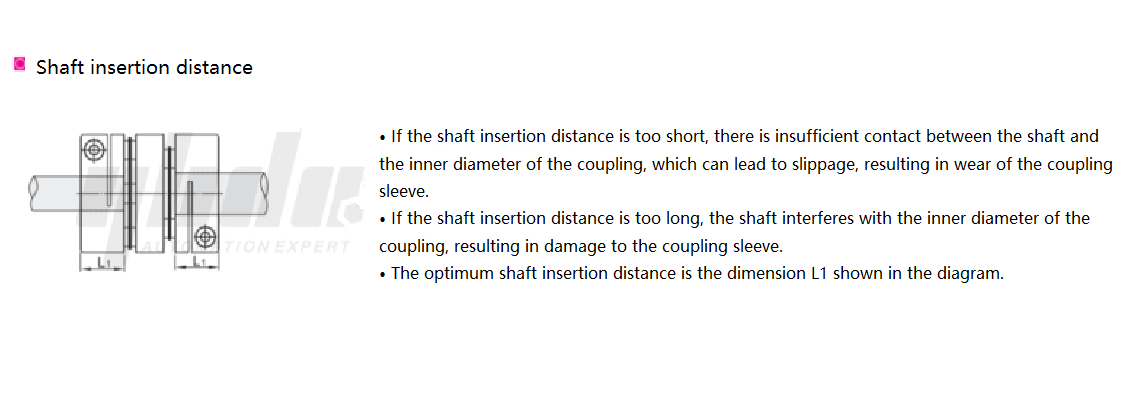

① The insertion distance of the shaft: (Single-side body width L1 ± axial allowable deviation)

② Clean the dust and dirt from the surface of the shaft.

③ Clean the inner hole of the coupling and apply machine oil or lubricant.

④ Insert the coupling into the shaft. If the bore diameter is tight, avoid using a hammer or hard metal to strike the installation to prevent deformation caused by impact.

⑤ After positioning, use a torque wrench (with the specified locking torque) to tighten the coupling according to the required torque.

|

Bolt diameter H |

12.9 Grade(N.m) |

8.8 Level stainless steel (N.m) |

|

M2 |

0.4 |

0.3 |

|

M2.5 |

0.9 |

0.65 |

|

M3 |

1.5 |

1.1 |

|

M4 |

3.6 |

2.7 |

|

M5 |

7.2 |

5.4 |

|

M6 |

12.2 |

9.2 |

|

M8 |

29.5 |

22 |

|

M10 |

59 |

44 |

|

M12 |

100 |

76 |

Locking torque

2. Caution:

(1) When disassembling, please do it when the unit is completely stopped and loosen the locking screws in order;

(2) When starting up the unit, it is necessary to check whether the nut of the plummer coupling has loosened or fallen off;

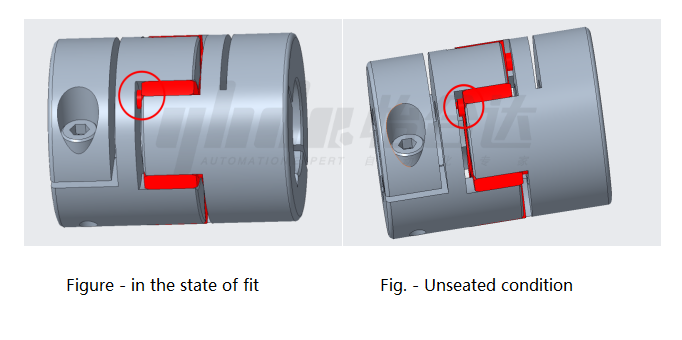

(3) The plummer pad step needs to be fitted with the end face of the body:

Note: If it is not used properly, the wear of the plum blossom pad will be accelerated, and uneven force will cause the plum blossom claw to break!!!

6. Regular Replacement of Plummer Pads

Plum blossom coupling need to regularly replace the plum blossom pad, the premise is that the enterprise has engineers to do a good job of routine maintenance, can find problems in a timely manner.

1. Keep a regular view of the plum elastic pad and maintenance, pay attention to the presence of wear and tear of the plum elastomer;

2. Maintenance after the completion of the work, to carry out a comprehensive inspection and maintenance of the plum coupling, timely replacement of worn parts.

7. How Long is Better to Replace the Plum Coupling Plum Pad?

As for the time period of replacement, this does not have a fixed value to refer to. Different machines and equipment on.

The use of different machines and equipment is different, if the installation problem may run 1 day directly worn out; and installed in place, depending on the actual transmission effect, half a year, a year may occur wear. Therefore, for the plum blossom coupling regular maintenance is essential.

Here also need to remind, in addition to natural wear, there are some subjective factors, will lead to plum pads, such as improper installation, uneven floor of the equipment, resulting in jerky operation of the equipment and so on.